An extensive reconstruction project was undertaken at a penthouse flat located in Knightsbridge, London, which involved the installation of a Class A fire retardant decking system across two levels of the residential terrace.

Utilising Porcelain Decking

The contractor our client hired to install a decking system to meet the fire regulations for balconies and terraces opted to use Exadeck porcelain decking and the Wallbarn Class A substructure system. The MetalPad D and I Plus rail joist, connectors, and decking fixing clips to fit the pedestals were supplied by Wallbarn, along with clips to secure the decking boards to the rails. Without any drawings or the chance to inspect the existing timber decking surface beforehand, our client was unable to give Wallbarn full details of the height thresholds or other pertinent technical data before beginning the project.

Once the pre-existing decking was taken away, they were left facing a highly intricate subdeck area.

A Terrace Of Variable Depth

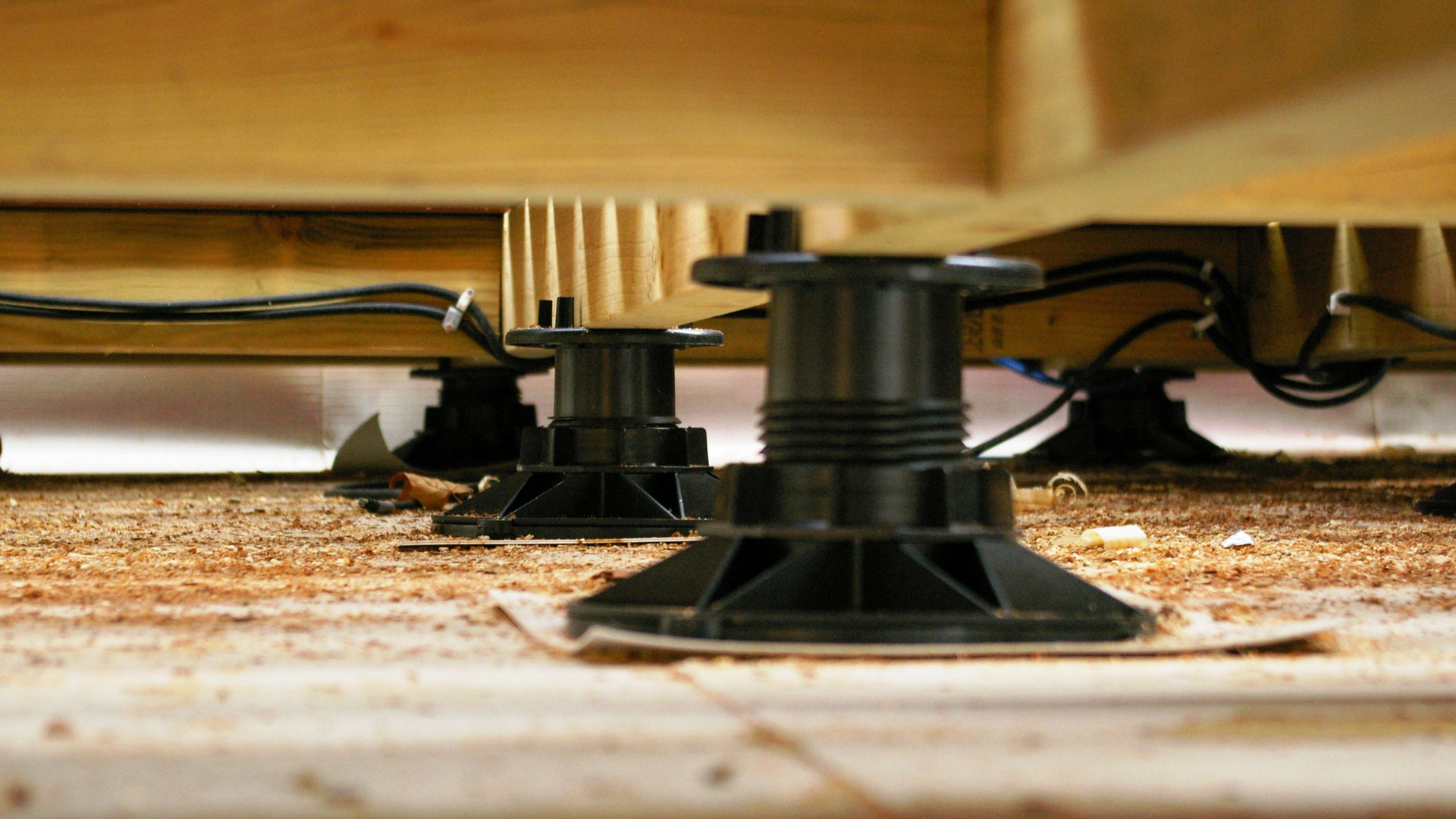

The terrace had a variable depth, was oddly shaped with multiple curves and bends, and there were unexpected protrusions from the surface. As a result, the height of the pedestals and rails required to make a horizontal deck was significantly varied. Wallbarn’s design group had to devise a plan for the whole terrace that would incorporate the MetalPad D adjustable pedestals connected to the I Plus and Double Box aluminium rails.

The upstands and pillars presented a major problem due to their height. As a result, we had to use the smallest 25-32mm pedestals for the 20mm and 25mm double box rail. However, for the surrounding area, we had to employ the 100mm I Plus rail on the higher MetalPad D pedestals. In certain cases, these pedestals were fixed to each other in two layers to ensure a secure fit.

Marked Benefits

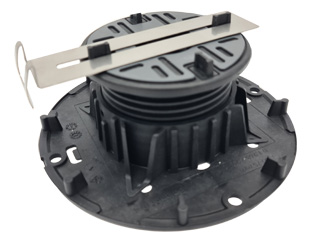

By combining Wallbarn MetalPad D with I Plus and Double Box rails, there is a marked benefit. The shapes of these rails fit snugly between the clips of the pedestal headpiece, meaning there is no need for any additional mechanical fixing of the rail. This setup allows for some flexibility in the decking system, allowing slight movement in the rails for optimal performance. This saved a lot of time when executing this intricate project.

The Wallbarn system stands out in the fact that it is designed to reduce the risks of stress points, which could happen when mechanical fixing points become loose. To achieve this, a framework of aluminium rails was put together with straight and right-angled brackets that link the rails across long segments and corners, and stainless steel screws where needed.

Solving A Major Challenge

A major challenge presented itself in the form of a large round window on one side of the terrace which called for extra pedestals and sections of rail substructure to ensure secure support for the decking on any sections where heavy foot traffic was expected; all of which had to be integrated into the general framework in order to keep the substructure stable.

To make matters more difficult, the client requested the decking to be installed in a diagonal pattern, thus necessitating the installation of an extra rail bearer, attached to the rail substructure with screw fixings, to support the decking boards at a 90-degree angle with the use of wing clip decking fixings.

The broad array of rail heights and types, all 60mm wide, enabled Wallbarn to meet the intricate requirements and create neat lines and a sufficient contact area for the installers to attach the clips to the board securely.

Exadeck Boards

The Exadeck boards are outstanding in quality and appropriate for the most grandiose projects. These planks have been rectified, which means an extra process of “re-mill” along their length and across each vertical plane has been performed.

The boards are without any curved or crooked shape, and they are laid perfectly flat on the 60mm wide rail. The lower side of the boards is also flat, allowing them to lie flush on the rail.

Boards that remain uncorrected may become warped at the edges, resulting in an unsteady platform even after the decking clip is put in place. The wing clips were attached to the aluminium rails using self-tapping stainless steel screws.

The mechanical screwdriver set to 6-7 TORQ was used to drive screws through the 2mm and 3mm thick aluminium rail faces. In most cases, they pre-drilled the rails. To cut through the Exadeck boards, 30mm diamond blades (available from Wallbarn) were necessary due to their toughness. The installers made diagonal cuts around the perimeter, producing ultra-clean and sharp cuts without shrapnel or defects in the porcelain material, resulting in minimal wastage.

A Two-Tiered Terrace

The penthouse was designed with a two-tiered terrace, necessitating the use of Exadeck for the decking on both levels and the staircase connecting them. The cut material was affixed to the stair frame and laid across the narrow, lower-height threshold of the terrace wrapping around the upper level, leading to the master bedroom where various changes in height were encountered.

The result was a beautiful, top-notch finish; a stark contrast to the original deck. Both the installer and the customer expressed great satisfaction with the final product.

It is evident that a great deal of effort must be put forth in order to achieve success. Hard work and dedication are essential components in the process of attaining success. One must be willing to put in the time and effort to bring about the desired results.