Wallbarn, a leading innovator in the field, offers a diverse range of substructure solutions tailored to meet various project requirements. This comprehensive guide delves into the intricacies of Wallbarn’s Class A1 Rail, Ultra-Low, and Plastic Pedestal Systems, providing construction professionals with the knowledge needed to make informed decisions for their specific applications.

As we navigate through the complexities of each system, we’ll explore their unique features, advantages, and ideal use cases. From fire-rated solutions to ultra-low profile options and versatile plastic pedestals, Wallbarn’s product lineup addresses a wide spectrum of construction challenges. By understanding the nuances of these substructure systems, project managers, architects, and contractors can optimise their designs, enhance safety compliance, and streamline installation processes.

Whether you’re working on a high-rise rooftop terrace, a ground-level patio, or a complex commercial space, this article will equip you with the insights necessary to select the most suitable Wallbarn substructure system. Let’s embark on this journey through innovative construction solutions, examining how each system can contribute to the success of your next project.

Understanding Substructure Systems

In the construction industry, substructure systems play a pivotal role in creating stable and level surfaces for various applications. These systems serve as the foundation for paving, decking, and other elevated surfaces, providing crucial support and allowing for adjustments to accommodate uneven substrates. Wallbarn’s range of substructure solutions caters to diverse project requirements, offering options that balance structural integrity, fire safety, and ease of installation.

The importance of selecting the right substructure cannot be overstated. It directly impacts the longevity, safety, and aesthetics of the finished surface. A well-chosen system can mitigate issues such as water pooling, uneven settling, and structural instability. Moreover, with increasing focus on fire safety regulations, particularly in high-rise buildings, the fire rating of substructure components has become a critical consideration for many projects.

Wallbarn’s substructure systems are designed to address these multifaceted challenges. The Class A1 Rail System, for instance, offers a non-combustible solution that meets stringent fire safety standards. The Ultra-Low System provides a solution for projects with height restrictions, while the Plastic Pedestal System offers versatility and cost-effectiveness for a wide range of applications.

Each system has its unique strengths and ideal use cases. Understanding these differences is crucial for construction professionals to make informed decisions that align with project specifications, building regulations, and client expectations. As we delve deeper into each system, we’ll explore how they can be leveraged to overcome common construction challenges and create superior finished surfaces.

The Class A1 Rail System: Fire-Rated Excellence

Wallbarn’s Class A1 Rail System represents the pinnacle of fire-rated substructure solutions. This system has been meticulously engineered to meet the most stringent fire safety requirements, making it an ideal choice for high-rise buildings and other structures where fire resistance is paramount. The Class A1 rating, in accordance with EN 13501-1:2018, ensures that the system does not contribute to fire spread or smoke production in the event of a fire.

One of the standout features of the Class A1 Rail System is its all-metal construction. Unlike systems that rely on plastic or rubber components, this system eliminates combustible materials entirely. This not only enhances fire safety but also contributes to the overall durability and longevity of the substructure. The absence of plastic gaskets or rubber elements means there’s no risk of degradation or compromise in the system’s integrity over time.

The system’s design prioritises both functionality and ease of installation. The aluminium rails and joists are engineered to integrate seamlessly with Wallbarn’s fire-rated MetalPad Ex adjustable pedestals. This integration is achieved through wing nut fixings, allowing for secure connections and precise height adjustments. The versatility of the system is evident in its ability to accommodate a wide range of height requirements, from as low as 41mm to significantly higher thresholds when utilising rail-to-rail headpieces.

For construction professionals, the Class A1 Rail System offers several key advantages:

- Compliance with Building Regulations: The system’s Class A1 rating ensures compliance with the latest fire safety regulations, particularly BS 8579, which is crucial for high-rise and public buildings.

- Structural Integrity: The all-metal construction provides superior load-bearing capacity and stability, allowing for greater spans between pedestals compared to traditional systems.

- Versatility: The system can be adapted to various project requirements, from low-profile installations to complex multi-level structures.

- Precision and Adjustability: The integration with MetalPad Ex pedestals allows for millimetre-precise adjustments, ensuring a perfectly level finished surface.

- Comprehensive Solution: Wallbarn provides all necessary fixings and connectors, streamlining the procurement and installation process.

The Class A1 Rail System is particularly well-suited for applications such as rooftop terraces, balconies, and elevated walkways in high-rise buildings. Its fire-resistant properties make it an excellent choice for projects where safety is a top priority, while its structural capabilities allow for creative design solutions in challenging spaces.

Ultra-Low System: Maximising Space Efficiency

In scenarios where height restrictions pose a significant challenge, Wallbarn’s Ultra-Low System emerges as an innovative solution. This system is specifically designed to address the needs of projects where traditional pedestal systems might be too tall, such as refurbishment works or installations over existing surfaces. The Ultra-Low System allows for the creation of level, elevated surfaces with minimal height increase, making it an invaluable tool in the construction professional’s arsenal.

The core of the Ultra-Low System lies in its specially designed low-profile components. These elements work in harmony to create a stable substructure that can accommodate height differences as small as 10mm. This level of precision is particularly useful in retrofit projects where maintaining door thresholds or meeting strict building height regulations is crucial.

Key features of the Ultra-Low System include:

- Minimal Height Increase: The system can create a level surface with as little as 10mm of additional height, ideal for projects with severe space constraints.

- Versatile Application: Suitable for both indoor and outdoor use, the system can support a variety of surface materials, including tiles, pavers, and decking.

- Adjustability: Despite its low profile, the system still offers adjustment capabilities to ensure a perfectly level finish.

- Drainage Consideration: The design incorporates drainage channels to prevent water accumulation, a crucial factor in outdoor applications.

- Compatibility: The Ultra-Low System can be integrated with other Wallbarn products for a comprehensive solution in mixed-height scenarios.

The Ultra-Low System finds its niche in various applications:

- Balcony Refurbishments: Where adding height might interfere with door openings or balustrade heights.

- Interior Flooring: For creating raised access floors with minimal impact on room height.

- Rooftop Terraces: In situations where additional weight and height are concerns for the existing structure.

- Accessible Design: Creating smooth transitions and level thresholds for improved accessibility.

For construction professionals, the Ultra-Low System offers a solution to what were once considered insurmountable challenges. It allows for the transformation of spaces that might otherwise be deemed unsuitable for elevated flooring or outdoor living areas. The system’s ability to work within tight height constraints opens up new possibilities for design and functionality, particularly in urban environments where space is at a premium.

Moreover, the Ultra-Low System’s compatibility with various surface materials provides flexibility in design choices. Whether the project calls for sleek porcelain tiles or robust decking boards, the system can be adapted to support the desired finish while maintaining its low-profile characteristics.

Plastic Pedestal System: Versatility and Cost-Effectiveness

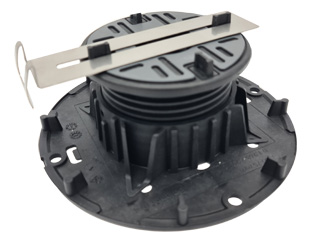

Wallbarn’s Plastic Pedestal System represents a versatile and economical solution for a wide range of substructure applications. This system combines durability, adjustability, and ease of installation, making it a popular choice for projects where fire rating is not a primary concern. The use of high-quality, UV-resistant plastics ensures longevity and reliability, even in challenging outdoor environments.

The Plastic Pedestal System is designed to accommodate various height requirements and surface materials. It consists of adjustable pedestals that can be fine-tuned to create a perfectly level surface, even on substrates with significant irregularities. This flexibility makes it an ideal choice for both new construction and renovation projects.

Key advantages of the Plastic Pedestal System include:

- Cost-Effectiveness: The use of high-quality plastics offers a more budget-friendly option compared to all-metal systems, without compromising on performance.

- Weight Reduction: The lightweight nature of plastic pedestals makes them easier to transport and handle on-site, potentially reducing labour costs.

- Corrosion Resistance: Unlike metal components, plastic pedestals are not susceptible to rust or corrosion, making them suitable for use in humid or coastal environments.

- Ease of Modification: Plastic pedestals can be easily cut or modified on-site to accommodate unique architectural features or obstacles.

- Thermal Insulation: The plastic material provides a degree of thermal insulation, which can be beneficial in certain applications.

The Plastic Pedestal System is well-suited for a variety of applications:

- Residential Patios and Decks: Providing a stable and adjustable base for outdoor living spaces.

- Commercial Plazas: Supporting paving in public areas where foot traffic is high.

- Rooftop Gardens: Creating level surfaces for green roof installations.

- Pool Surrounds: Offering a durable solution that can withstand exposure to chlorinated water.

For construction professionals, the Plastic Pedestal System offers a balance of performance and value. Its versatility allows for creative solutions in diverse project scenarios, from straightforward patio installations to complex multi-level designs. The system’s adjustability is particularly valuable when working with existing structures or uneven substrates, as it allows for precise levelling without the need for extensive preparatory work.

Moreover, the Plastic Pedestal System’s compatibility with various surface materials provides flexibility in design choices. Whether the project calls for natural stone pavers, composite decking, or ceramic tiles, the system can be adapted to support the desired finish while ensuring proper drainage and ventilation beneath the surface.

Comparing System Performance

When selecting a substructure system for a construction project, understanding the performance characteristics of each option is crucial. Wallbarn’s Class A1 Rail, Ultra-Low, and Plastic Pedestal Systems each offer unique strengths that cater to different project requirements. This section provides a comparative analysis of these systems, focusing on key performance metrics that are essential for informed decision-making.

Load-Bearing Capacity

The load-bearing capacity of a substructure system is a critical factor, particularly for commercial and high-traffic areas. Here’s how the systems compare:

- Class A1 Rail System: Offers the highest load-bearing capacity due to its all-metal construction. It’s ideal for heavy-duty applications and can support significant weight over larger spans.

- Ultra-Low System: Despite its compact profile, this system provides adequate support for typical residential and light commercial use. However, it may have limitations for extremely heavy loads.

- Plastic Pedestal System: While not as robust as the metal systems, high-quality plastic pedestals can support substantial weights. They are suitable for most residential and many commercial applications.

Height Adjustability

The ability to adjust height is crucial for creating level surfaces over uneven substrates:

- Class A1 Rail System: Offers a wide range of height adjustability, from as low as 41mm to significant heights using rail-to-rail connections.

- Ultra-Low System: Specialises in minimal height adjustments, starting from as low as 10mm, making it ideal for retrofit projects with strict height limitations.

- Plastic Pedestal System: Provides a good range of height adjustability, typically from about 17mm to 1020mm, depending on the specific model.

Fire Resistance

Fire safety is a critical consideration, especially in high-rise buildings:

- Class A1 Rail System: Achieves the highest fire rating (A1), making it the go-to choice for projects with stringent fire safety requirements.

- Ultra-Low System: While not achieving A1 rating, it can be manufactured with fire-retardant materials to meet specific project requirements.

- Plastic Pedestal System: Generally does not offer high fire resistance, making it more suitable for applications where fire rating is not a primary concern.

Ease of Installation

The efficiency of installation can significantly impact project timelines and costs:

- Class A1 Rail System: Requires more specialised installation due to its metal components but offers precise adjustments and secure connections.

- Ultra-Low System: Generally quick to install, especially in scenarios with minimal height variations.

- Plastic Pedestal System: Known for its ease of installation, with components that are lightweight and easy to handle.

Durability and Longevity

The long-term performance of the substructure is crucial for the overall lifespan of the installation:

- Class A1 Rail System: Offers exceptional durability due to its all-metal construction, resistant to weathering and degradation.

- Ultra-Low System: Designed for longevity, with materials chosen to withstand various environmental conditions.

- Plastic Pedestal System: While not as durable as metal systems, high-quality UV-resistant plastics offer good longevity, particularly in less demanding environments.

Cost Considerations

Budget often plays a significant role in system selection:

- Class A1 Rail System: Generally the most expensive option due to its premium materials and fire-rated status.

- Ultra-Low System: Mid-range in terms of cost, offering a balance between performance and affordability.

- Plastic Pedestal System: Typically the most cost-effective option, making it attractive for large-scale projects with less demanding requirements.

By comparing these performance aspects, construction professionals can make informed decisions based on their specific project needs. Each system offers a unique set of advantages, and the best choice will depend on factors such as building regulations, project specifications, environmental conditions, and budget constraints.

Installation Techniques and Best Practices

Proper installation is crucial for the longevity and performance of any substructure system. While Wallbarn’s systems are designed for ease of use, following best practices ensures optimal results. This section outlines key installation techniques for each system, highlighting important considerations for construction professionals.

Class A1 Rail System Installation

- Substrate Preparation:

- Ensure the substrate is clean, dry, and capable of supporting the expected loads.

- Address any drainage issues before installation.

- Pedestal Placement:

- Begin by placing MetalPad Ex pedestals at the perimeter and key structural points.

- Use string lines or laser levels to establish the desired height and slope.

- Rail Installation:

- Secure aluminium rails to the pedestals using the provided wing nut fixings.

- Ensure rails are level and properly aligned.

- Headpiece Attachment:

- Attach appropriate headpieces to the rails for the intended surface material.

- Adjust headpieces along the rail for perfect alignment with tiles or decking.

- Final Adjustments:

- Make fine adjustments to ensure a perfectly level surface.

- Check stability and make any necessary reinforcements.

Ultra-Low System Installation

- Surface Assessment:

- Carefully evaluate the existing surface for any irregularities or damage.

- Clean thoroughly and repair any significant defects.

- Component Layout:

- Plan the layout of the ultra-low components based on the surface material dimensions.

- Mark key points and edges to guide installation.

- Height Adjustment:

- Use the system’s minimal adjustment features to address slight variations in the substrate.

- Ensure consistent support across the entire surface area.

- Drainage Consideration:

- Pay special attention to maintaining proper drainage channels within the system.

- Align components to facilitate water flow away from the structure.

- Surface Material Installation:

- Carefully place tiles, pavers, or decking onto the ultra-low supports.

- Use spacers to ensure consistent gaps between surface elements.

Plastic Pedestal System Installation

- Pedestal Distribution:

- Calculate and mark pedestal positions based on the surface material and expected loads.

- Start from a fixed point (e.g., a wall) and work outwards.

- Height Setting:

- Adjust pedestal heights to create the desired slope for drainage.

- Use a spirit level or laser level for accuracy.

- Stability Checks:

- Ensure each pedestal is stable and fully supported by the substrate.

- Use additional base plates or shims if necessary.

- Surface Material Laying:

- Begin laying tiles, pavers, or decking boards from one corner.

- Use the pedestal’s inbuilt spacer tabs for consistent gaps.

- Edge Treatment:

- Pay special attention to edges and corners, using appropriate edge support pieces.

- Ensure a clean, finished look at all perimeters.

General Best Practices

- Safety First: Always adhere to site safety protocols and wear appropriate personal protective equipment.

- Tool Preparation: Have all necessary tools on hand, including levels, measuring devices, and cutting tools.

- Material Acclimation: Allow surface materials to acclimate to site conditions before installation.

- Regular Checks: Perform frequent level and stability checks throughout the installation process.

- Documentation: Keep detailed records of the installation process, including any deviations from the original plan.

By following these installation techniques and best practices, construction professionals can ensure that Wallbarn’s substructure systems perform to their full potential. Proper installation not only enhances the immediate aesthetic and functional qualities of the finished surface but also contributes to long-term durability and user satisfaction.

Maintenance and Long-Term Care

Ensuring the longevity and optimal performance of Wallbarn’s substructure systems requires a proactive approach to maintenance and long-term care. While these systems are designed for durability, regular attention can prevent minor issues from escalating and maintain the integrity of the installation over time. This section outlines key maintenance strategies and long-term care considerations for each system.

Class A1 Rail System Maintenance

- Regular Inspections:

- Conduct visual inspections at least twice a year, focusing on joint integrity and rail alignment.

- Check for any signs of corrosion, particularly in coastal or industrial environments.

- Cleaning Procedures:

- Remove debris from between rails and pedestals to prevent water accumulation.

- Use non-abrasive cleaners to remove any build-up on metal surfaces.

- Adjustment Checks:

- Periodically verify that all connections remain tight and secure.

- Re-adjust pedestals if any settling or movement is detected.

- Drainage Maintenance:

- Ensure drainage channels remain clear and functional.

- Address any areas where water pooling is observed.

- Surface Material Care:

- Maintain the overlying surface material according to manufacturer recommendations.

- Promptly address any issues that could impact the substructure, such as cracked tiles.

Ultra-Low System Maintenance

- Gap Inspection:

- Regularly check the gaps between surface materials to ensure they remain consistent.

- Clear any debris that may accumulate in these spaces.

- Level Monitoring:

- Use a spirit level to check for any changes in surface levelness over time.

- Make minor adjustments as needed to maintain a perfectly level surface.

- Moisture Management:

- Inspect for any signs of moisture retention or water damage.

- Ensure that the system’s drainage features are functioning correctly.

- Component Integrity:

- Check for any signs of wear or damage to the ultra-low components.

- Replace any damaged parts promptly to maintain system integrity.

- Seasonal Considerations:

- Pay extra attention to the system after extreme weather events.

- Address any frost heave or thermal expansion issues in regions with significant temperature fluctuations.

Plastic Pedestal System Maintenance

- Stability Checks:

- Periodically test the stability of the surface by walking on it and noting any movement.

- Adjust or replace pedestals that show signs of instability.

- UV Exposure Management:

- Monitor for any signs of UV degradation, particularly in areas with intense sunlight.

- Consider applying UV-protective coatings to exposed plastic components if recommended by the manufacturer.

- Cleaning Regimen:

- Clean pedestals and spacers annually to remove dirt and prevent algae growth.

- Use mild detergents and avoid harsh chemicals that could degrade the plastic.

- Load Distribution:

- Regularly assess the load distribution across the system, especially in high-traffic areas.

- Redistribute or add pedestals if uneven wear is observed.

- Freeze-Thaw Considerations:

- In climates with freeze-thaw cycles, inspect for any damage or displacement after winter.

- Ensure proper drainage to prevent water accumulation and potential frost damage.

General Long-Term Care Strategies

- Documentation:

- Maintain a log of all inspections, maintenance activities, and any adjustments made.

- Keep original installation plans and product specifications for reference.

- Professional Assessments:

- Consider annual professional inspections, especially for large or complex installations.

- Engage specialists for any major repairs or adjustments.

- Preventive Measures:

- Apply appropriate sealants or protective coatings as recommended by Wallbarn.

- Address any substrate issues promptly to prevent impact on the substructure.

- User Education:

- Provide guidelines to property owners or facility managers on proper use and basic maintenance.

- Emphasise the importance of prompt reporting of any issues noticed.

- Lifecycle Planning:

- Develop a long-term maintenance plan that includes expected component lifespans and replacement schedules.

- Budget for periodic system upgrades or replacements as part of overall facility management.

By implementing these maintenance and long-term care strategies, construction professionals can ensure that Wallbarn’s substructure systems continue to perform optimally throughout their intended lifespan. Regular attention to these aspects not only preserves the functional integrity of the installation but also protects the investment made in the substructure system.

Future Trends and Innovations

The construction industry is continually evolving, driven by technological advancements, changing regulations, and shifting market demands. Wallbarn, as a leader in substructure systems, is at the forefront of these developments, continuously innovating to meet future challenges. This section explores emerging trends and potential innovations in substructure technology, with a focus on how Wallbarn is positioning itself to address these future needs.

Sustainable Materials and Practices

As environmental concerns become increasingly prominent, the demand for sustainable construction materials and methods is growing. Wallbarn is actively researching and developing eco-friendly alternatives for its substructure systems:

- Recycled Content: Increasing the use of recycled materials in plastic pedestal production without compromising on strength or durability.

- Biodegradable Options: Exploring biodegradable materials for temporary or short-term installations, reducing long-term environmental impact.

- Carbon Footprint Reduction: Implementing manufacturing processes that minimize carbon emissions and energy consumption.

- End-of-Life Considerations: Designing systems with easier disassembly and recyclability in mind, supporting circular economy principles.

Smart Building Integration

The rise of smart buildings and the Internet of Things (IoT) presents new opportunities for substructure systems to contribute to building intelligence:

- Sensor Integration: Developing pedestals with built-in sensors to monitor structural health, detect water ingress, or measure foot traffic.

- Data Collection: Creating systems that can collect and transmit data on temperature, humidity, and other environmental factors to building management systems.

- Adaptive Systems: Exploring the potential for substructures that can automatically adjust to changing conditions, such as thermal expansion or settling.

Enhanced Fire Safety Features

With fire safety remaining a critical concern, especially in high-rise buildings, Wallbarn continues to innovate in fire-resistant technologies:

- Advanced Materials: Researching new materials that offer even better fire resistance while maintaining structural integrity.

- Integrated Fire Suppression: Exploring the possibility of incorporating fire suppression features directly into substructure components.

- Thermal Barriers: Developing systems that provide enhanced thermal insulation to slow the spread of fire between floors.

Modular and Prefabricated Solutions

The trend towards off-site construction and modular building methods is influencing substructure design:

- Pre-assembled Units: Creating substructure modules that can be quickly installed on-site, reducing installation time and labour costs.

- Customizable Systems: Developing flexible, modular components that can be easily adapted to various project requirements.

- Integration with BIM: Enhancing compatibility with Building Information Modelling (BIM) to streamline design and installation processes.

Extreme Weather Resilience

As climate change leads to more frequent extreme weather events, substructure systems need to adapt:

- Wind Resistance: Developing systems with improved wind uplift resistance for rooftop and elevated installations.

- Flood Mitigation: Creating substructures that can better withstand temporary flooding or water exposure.

- Temperature Extremes: Researching materials and designs that maintain stability and performance across a wider range of temperatures.

Acoustic Performance

With increasing focus on occupant comfort, especially in multi-use buildings, acoustic properties are gaining importance:

- Sound Dampening: Incorporating sound-absorbing materials into substructure components to reduce noise transmission between floors.

- Vibration Control: Developing systems that minimize vibration transfer, particularly important in commercial and mixed-use spaces.

Accessibility and Universal Design

As regulations and societal expectations around accessibility evolve, substructure systems are adapting to support more inclusive designs:

- Seamless Transitions: Refining ultra-low profile systems to create smoother transitions between different floor levels and materials.

- Adjustable Systems: Developing easily adjustable systems that can be modified to meet changing accessibility needs over time.

Advanced Load Distribution

Innovations in load distribution technology are opening new possibilities for substructure design:

- Dynamic Load Management: Exploring systems that can actively redistribute loads in response to changing conditions or usage patterns.

- Lightweight High-Strength Materials: Researching new materials that offer superior strength-to-weight ratios, allowing for larger spans and reduced structural requirements.

Wallbarn’s commitment to innovation ensures that it remains at the cutting edge of substructure technology. By anticipating future trends and actively developing solutions to meet emerging challenges, Wallbarn continues to provide construction professionals with advanced, reliable, and forward-thinking substructure systems. As the industry evolves, Wallbarn’s products will play a crucial role in shaping the buildings of tomorrow, combining safety, sustainability, and performance in increasingly sophisticated ways.

Conclusion

As we’ve explored throughout this comprehensive guide, choosing the right substructure system is a critical decision that impacts the success, safety, and longevity of construction projects. Wallbarn’s range of solutions, including the Class A1 Rail, Ultra-Low, and Plastic Pedestal Systems, offers construction professionals a versatile toolkit to address diverse project requirements and challenges.

The Class A1 Rail System stands out for its exceptional fire safety properties and structural integrity, making it ideal for high-rise buildings and projects with stringent safety regulations. The Ultra-Low System provides an innovative solution for projects with severe height restrictions, enabling the creation of level surfaces in challenging retrofit scenarios. The Plastic Pedestal System offers a balance of versatility, cost-effectiveness, and ease of installation, suitable for a wide range of applications.

Each system has its unique strengths, and the choice between them depends on factors such as fire safety requirements, height constraints, load-bearing needs, and budget considerations. By understanding the specific characteristics and performance attributes of each system, construction professionals can make informed decisions that align with project specifications and client expectations.

The case studies presented demonstrate the real-world applicability and success of Wallbarn’s systems across various project types, from luxury high-rises to historical renovations. These examples highlight the adaptability and reliability of Wallbarn’s solutions in addressing complex construction challenges.

Looking to the future, Wallbarn continues to innovate, focusing on sustainability, smart building integration, and enhanced performance in extreme conditions. This forward-thinking approach ensures that Wallbarn’s substructure systems will continue to meet the evolving needs of the construction industry.

In conclusion, the selection of an appropriate substructure system is a decision that requires careful consideration of multiple factors. Wallbarn’s range of solutions provides construction professionals with the tools they need to create safe, durable, and high-performance elevated surfaces. By leveraging the strengths of each system and staying informed about emerging trends and innovations, project managers, architects, and contractors can ensure the success of their projects and contribute to the creation of better-built environments.

As the construction landscape continues to evolve, Wallbarn remains committed to providing cutting-edge substructure solutions that meet the challenges of today and anticipate the needs of tomorrow. Through ongoing research, development, and customer engagement, Wallbarn will continue to play a crucial role in shaping the future of construction technology and practices.