Fire safety, structural integrity, and security are critical when designing public walkways, terraces, podiums, and balconies. Wallbarn’s ExaDeck fire-rated decking system is a fully non-combustible Class A system, independently tested to exceed safety standards while delivering unmatched strength, durability, and minimal maintenance requirements.

Understanding Commission Decision 96/603/EC, BS 8579 & EN 13501-1:2018 in Fire Safety Compliance

EN 13501-1:2018 is the European standard for fire classification of construction products. A standard for attaining the fire rating of construction products, defining Class A materials as those that do not contribute to fire in any way.

Decision 96/603/EC (amended in 2003) establishes the classification of construction materials based on their reaction to fire. Under this Directive, certain materials which are deemed to be Class A, include steel, aluminium, and ceramics—all of which are the primary components of Wallbarn’s ExaDeck system – do not require a physical fire test or fire test certificate.

BS 8579:2020 is a British Standard and provides specific guidance for the design of balconies and terraces, reinforcing the requirement for non-combustible materials in external applications to prevent fire spread in high-rise environments.

By ensuring that every element of our system meets these rigorous standards, Wallbarn delivers a fully compliant, fire-safe decking solution that prioritises safety, durability, and long-term performance.

The system incorporates:

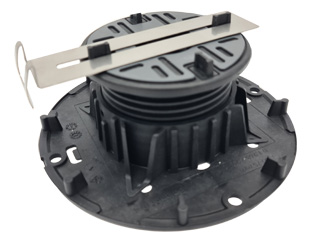

- Steel (MetalPad Ex adjustable pedestals)

- Aluminium (I-Plus or Box rail joists and W Clip hidden fixing system)

- Ceramic (ExaDeck extruded porcelain boards)

- Class A Fixings & Connections

Each of these materials are deemed to be Class A under EC Decision 96/603/EC, ensuring the system is entirely non-combustible.

The only element requiring a physical fire test was the Zintek 200 coating on the MetalPad Ex pedestals. Although this coating does not contribute to fire, we proactively sought independent testing from Warrington Fire, where it was classified as Class A2.

These independent test reports are readily available on our website, ensuring transparency and confidence in our system’s fire performance.

The Strength & Security of the System

Safety is not just about fire resistance—structural integrity is just as crucial. Wallbarn’s ExaDeck system has undergone rigorous independent testing to ensure its ability to withstand high foot traffic, heavy loads, and extreme weather conditions.

- MetalPad Ex pedestals have a weight tolerance exceeding 5 tonnes—this increases to 7 tonnes when used with the optional spreader plate.

- Aluminium joists have been independently tested for weight tolerance and displacement, even at our recommended pedestal spacing.

- ExaDeck ceramic boards have also been independently tested for load-bearing capacity. It meets and exceeds all requirements under our recommended 400mm joist centres.

Unlike many commercial decking systems that require joist centres of 250mm–350mm, our superior-strength joists and boards allow for 400mm joist centres as standard—even in commercial settings. This not only ensures a stronger system but also reduces material costs and installation time.

Minimising Movement for Maximum Safety

A secure decking system should not allow movement or rocking, as this can increase accident risk.

- Joist Width & Stability: While many joists are only 40mm across, Wallbarn’s aluminium joists are 60mm for a broader, more secure fixing surface.

- W Clip Hidden Fixing System: Specifically designed to fit the side milling profile of the ExaDeck boards and spanning the I-Plus aluminium joists fully, this 60mm-wide clip fully covers the joist, eliminating glare while securing the boards in place. This prevents board movement, rocking, or shifting, ensuring the deck remains solid underfoot.

- Exadeck has superior weight tolerance to other decking materials, with a load tolerance of 4.41 kN (approx. 450 kg) at 400mm fixing centres.

- The ExaDeck boards are double rectified. This means two additional processes are undertaken during manufacture. The boards are cut on two planes: sideways along the length of the board to ensure each board is dead straight with no tolerances or bending along the length; and on the top and bottom surface also to ensure that the boards sit dead flat onto the rails without rocking or any movement, giving a secure connection in the long term.

- Slip Resistance: The ExaDeck system offers R11 slip resistance, reducing the likelihood of slips and falls, even in wet conditions.

A rock-solid, non-slip system is essential for pedestrian safety in public spaces, commercial terraces, and high-traffic areas – and ExaDeck delivers exactly that.

Proven Performance beyond the Lab

While independent lab testing is vital, real-world performance is just as important. Over the past two years, ExaDeck has been installed in multiple retrofit, refurbishment, and new-build projects across a variety of high-exposure environments, including:

- Public walkways with constant foot traffic

- Coastal areas exposed to extreme weather conditions

- High-rise podiums, terraces, and balconies

For coastal and high-wind environments, independent wind uplift tests were conducted. The ExaDeck board section achieved an upwards force of 7.46kN/m², equivalent to wind speeds exceeding 200mph—reinforcing its security in exposed locations.

Minimal Maintenance, Luxury Appearance, Maximum Longevity

One of the biggest advantages of the ExaDeck system is its low maintenance requirements and exceptional lifespan.

- The Exadeck ceramic boards are super strong with excellent scratch resistance.

- Exadeck has a luxurious, beautiful aesthetic with a wood grain effect in stark contrast to the industrial appearance to other decking materials.

- The boards, crucially, will not become hot underfoot in high temperatures or under direct sunlight.

- Exadeck has superior stain resistance, making ideal for public areas such as restaurant terraces.

- Beautiful clean lines from the double rectified boards and uniform spacing of the W Clip fixings are achieved across the decking area.

- The substructure (MetalPad Ex pedestals & aluminium joists) comes with a 15-year limited warranty and a life expectancy exceeding 50 years.

- The ExaDeck ceramic board is backed by a 25-year warranty and has a life expectancy exceeding 100 years.

Once installed, maintenance is minimal. The system only requires:

- Jet washing or cleaning with mild detergents

- No harsh chemicals, solvents, or specialist tools

- No annual sealants or protective coatings

- The top surface will not delaminate

Unlike other decking materials, ExaDeck does not degrade, warp, or require ongoing treatments, making it an incredibly cost-effective and long-lasting solution.

The Safest Choice for Public & High-rise Decking

Every component of the ExaDeck fire-rated system has been carefully engineered, rigorously tested, and proven in real-world applications to deliver:

- Full compliance to all relevant fire regulations and standards

- Class A fire performance with independently verified testing

- Industry-leading strength, weight tolerance & wind resistance

- Superior slip & stain resistance

- Minimal maintenance & exceptional long-term durability

- 15-year substructure warranty & 25-year board warranty with life expectancy exceeding 50 years

With fire safety, strength, and security at its core, ExaDeck is the premium quality, luxury finish Class A solution for non-combustible, high-performance decking schemes.

For more information, contact us today to discuss your project requirements.