Decking

Tropical Hardwood

What is it?

- All of our real wood species are of the highest quality and stability

- All species are sourced following the most stringent sustainability protocols

- Hardwood available in timber tiles

Ipe

Lapacho or Brazilian Walnut – a tropical hardwood originating from South America. Widely regarded as one of the best species of timber for decking.

Boards available in lengths of 1200mm and 1800mm and either 90mm wide or 140mm wide giving a great deal of flexibility.

It has a greenish brown appearance and because of its tight grain is popular for its high resistance to mildew, termites and rotting. It is very low maintenance and is used extensively in marine and exterior construction due to its resistance to water. It dries very well and becomes extremely hard, which means it has to be pre-drilled and cut with a mechanical saw. Ipe has a fire rating of Euroclass B and will last up to 25 years. It is nicknamed “ironwood”.

Cumaru

Cumaru (Brazil) is another hardwearing timber.

It is similar to ipe but has a rich chestnut colour. It has very good strength and rot-resistant properties. Ideal for clients who favour a lighter-coloured wood finish.

Timber Decking Tiles

Timber decking tiles are a great solution, especially for low-height thresholds and are quick & easy to install.

- Achieve thresholds as low as 37mm

- Long-lasting, attractive decking suitable for the British climate

- Durable hardwood – lasts over 15 years

- No specialist carpentry required

- Pre-formed tiles – easy to cut for detailing

- No joists required – avoid damage to your membrane

Ideal for ultra-low thresholds

- Our tiles are just 30mm in height which means combined with our 7mm fixed height pedestal you can deck up to a threshold as low as 37mm

- Traditional decking methods using timber joists, even if suspended on a super-low support pad, will only allow you to deck up to a threshold of 130mm or higher

Just like laying slabs

- Uniform size and space between decking

- Unsightly items such as drainage outlets, cables and pipes are hidden beneath the tiles

- Tile weight holds them in place

- No need to fix anything to the deck

- Futureproofed: take up a tile to inspect your deck with minimal disruption

Installation

We have a number of helpful videos providing guidance on our products:

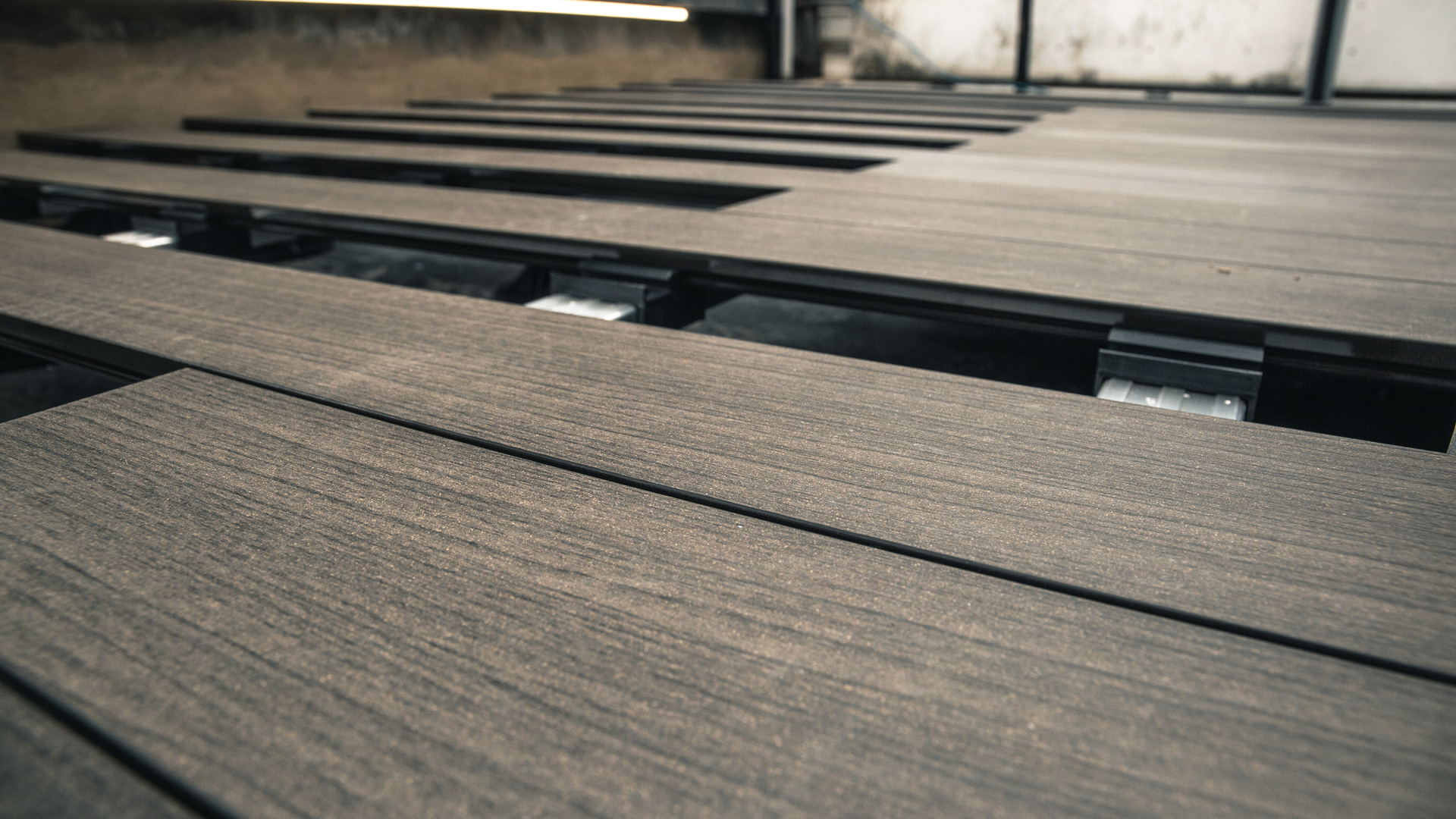

Aluminium Joists

Our aluminium joists mimics the build of traditional timber substructure but with many key advantages.

- Can achieve ultra low height thresholds. As little as 55mm total buildup depending on board choice.

- Will not rot, warp or bend like timber joists.

- 100% recyclable Material

- Aluminium will not expand and contract like timber joists

- Lightweight and easy to work with Material.

- We have a special headpiece on our pedestals to accommodate the aluminium joists

- Depending on board choice, we have a number of hidden fixings available. i-Fly, 4 Hook, Remo

Composite Joists

Our composite joists are sturdy and ideal for use with almost any board on the market.

iDecking EasyChange

The Easychange i-Decking system uses a hidden fixing that allows for the boards to be unlocked using a key. This is ideal for when you need access to the sub floor for maintenance or repairs.

- Sustainable, non-rotting decking system

- Integrated substructure and deck board

- Clean lines, uninterrupted surface

- Composite, bamboo and tropical hardwood options available

- Bare foot friendly

- Ideal for low thresholds (whole system from 83mm)

- Faster, easier installation

- Ideal for domestic or commercial use

NBS Source

BIM Library

Physical properties

| Tile dimensions | 500mm x 500mm | |||||||

|---|---|---|---|---|---|---|---|---|

| Tile thickness | 30mm | |||||||

| Number of slats / boards | 7 boards - 15x67x500mm | |||||||

| Upper finish | casselled / ridged | |||||||

| Gap between slats | 5mm | |||||||

| Reinforcement | 3 battens - 15x67x500mm battens fixed diagonally to underside in Z shape | |||||||

| Fixings | 2 x Stainless Steel Screws per slat / board 1 x Additional Stainless Steel Screw per cross batten | |||||||

| weight tolerance per tile - edge | 200kg - 400kg | |||||||

| weight tolerance per tile - centre | 100kg | |||||||

| Reaction to UV | Will fade and turn grey over time Regular application of oil will restore original colour | |||||||

| Raw material | IPE | CUMARU | ||||||

| botanical name | Tabebuia spp | Dipteryx spp. | ||||||

| average mass density | 1,092 Kg/m3 | 1,021 Kg/m3 | ||||||

| dimensional stability (UNI 11538-1) (**) | Class C. Recommended minimum slenderness coefficient 1/6 | Class C. | ||||||

| average Monnin hardness (*) | 14.60 | 13.10 | ||||||

| damp climate deformations | type deformation | values detected | reference values (UNI 11538-1) | outcome | type deformation | values detected | reference values (UNI 11538-1) | outcome |

| bow | 0.14% | < 1% on width | PASS | bow | 0.09% | < 1% on width | PASS | |

| spring | 0.08 mm/m | < 2 mm/m | PASS | spring | 0.48 mm/m | < 2 mm/m | PASS | |

| twist | 1.6 mm/m | < 2 mm/m | PASS | twist | 1.08 mm/m | < 2 mm/m | PASS | |

| dry climate deformations | type deformation | values detected | reference values (UNI 11538-1) | outcome | type deformation | values detected | reference values (UNI 11538-1) | outcome |

| bow | 0.30% | < 1% on width | PASS | bow | 0.11% | < 1% on width | PASS | |

| spring | 0.36 mm/m | < 2 mm/m | PASS | spring | 0.60 mm/m | < 2 mm/m | PASS | |

| twist | 2.96 mm/m | < 2 mm/m | FAIL | twist | 3.24 mm/m | < 2 mm/m | FAIL | |

| moisture | type deformation | values detected | reference values (UNI 11538-1) | outcome | type deformation | values detected | reference values (UNI 11538-1) | outcome |

| bow | 13.90% | <18% | PASS | bow | 12.10% | <18% | PASS | |

| spring | 15.80% | <18% | PASS | spring | 13.90% | <18% | PASS | |

| twist | 8.40% | <18% | PASS | twist | 7.90% | <18% | PASS |

Mechanical properties

| Raw material | IPE | CUMARU | |

|---|---|---|---|

| average bending strength | 191 Mpa | 190 MPa | |

| average bending strength after freeze/thaw cycles | untreated wood | 149 Mpa | 166 Mpa |

| oiled wood | 184 Mpa | ||

| average bending strength after freeze-icing cycles | untreated wood | 205 Mpa | 141 Mpa |

| oiled wood | 217 Mpa | ||

| average bending strength after heat-rain and heat-cold cycles | untreated wood | 182 Mpa | 173 Mpa |

| oiled wood | 194 Mpa | ||

| average modulus of elasticity | 21,114 Mpa | 20,997 Mpa | |

| average crushing strength | 95 Mpa | 103 Mpa | |

| stiletto heel impression (UNI 4712) | value - 0.04 mm | PASS |

Natural durability (UNI EN 335, UNI EN 350)

| Raw material | IPE | CUMARU |

|---|---|---|

| fungi (*) | very durable - class 1 | very durable - class 1 |

| dry wood borers (*) | durable - class D | durable - class D |

| termites (*) | durable - class D | durable - class D |

| treatability (*) | not permeable - class 4 | not permeable - class 4 |

| use class (*) | outside in contact with the ground and/or fresh water - class 4 | outside in contact with the ground and/or fresh water - class 4 |

| use in marine environments | class 5 (*) |

Properties by conditions of use (IPE)

| BCRA slipperiness (Min.Decree 236/89, Pres. Decree 503/96) | conditions | direction | values detected untreated | values detected oiled | reference values | outcome |

|---|---|---|---|---|---|---|

| rubber pad wet surface | parallel | 0.67 | 0.69 | > 0.40 | PASS | |

| perpendicular | 0.78 | 0.82 | > 0.40 | PASS | ||

| rubber pad dry surface | parallel | 0.73 | 0.72 | > 0.40 | PASS | |

| perpendicular | 0.78 | 0.76 | > 0.40 | PASS | ||

| leather pad dry surface | parallel | 0.42 | 0.52 | > 0.40 | PASS | |

| perpendicular | 0.43 | 0.51 | > 0.40 | PASS | ||

| grade R slipperiness (DIN 51130) | R10 | |||||

| grade A+B+C slipperiness (DIN 51097) | A+B+C | |||||

| fire reaction (UNI EN ISO 9239, UNI EN ISO 11925-2, UNI EN 13501-1) | Cfl-s1 |

Properties by conditions of use (Cumaru)

| BCRA slipperiness (Min.Decree 236/89, Pres. Decree 503/96) | conditions | direction | values detected | reference values | outcome |

|---|---|---|---|---|---|

| rubber pad wet surface | parallel | 0.72 | > 0.40 | PASS | |

| perpendicular | 0.81 | > 0.40 | PASS | ||

| rubber pad dry surface | parallel | 0.65 | > 0.40 | PASS | |

| perpendicular | 0.7 | > 0.40 | PASS | ||

| leather pad dry surface | parallel | 0.38 | > 0.40 | FAIL | |

| perpendicular | 0.47 | > 0.40 | PASS |

Brochures

Technical Datasheets

- Technical Data for Hardwood

- Wallbarn IPE Timber Tiles Datasheet

- Slip Test for Ipe and Cumaru tiles – BS7976 – 20 April 2016