As industry professionals seek solutions that not only meet stringent safety standards but also offer enhanced stability and streamlined installation processes, Wallbarn has emerged as a pioneering force. This comprehensive exploration delves into Wallbarn’s cutting-edge Class A1 Rail, Ultra-Low, and Plastic Pedestal Substructure Systems, unveiling how these innovations are reshaping the landscape of exterior decking, paving, and construction projects.

From balconies and terraces to podiums and flat roofs, the challenges faced by builders and designers are multifaceted. The need for fire-resistant materials, adaptable height solutions, and systems that can withstand significant loads while providing lateral stability has driven the development of Wallbarn’s advanced substructure solutions. As we navigate through the intricacies of these systems, we’ll uncover how they not only meet but exceed industry standards, offering unparalleled performance, versatility, and ease of use.

Whether you’re a seasoned contractor, an ambitious architect, or a discerning property developer, understanding the capabilities and benefits of these innovative substructure systems is crucial. Join us as we explore how Wallbarn’s commitment to quality, safety, and efficiency is setting new benchmarks in the construction industry, providing solutions that are not just fit for purpose, but designed to elevate the entire building process.

Understanding Wallbarn’s Class A1 Rail System

Wallbarn’s Class A1 Rail System represents a significant leap forward in substructure technology for exterior decking and paving applications. This innovative system has been meticulously engineered to provide superior stability, fire resistance, and ease of installation, making it an ideal choice for a wide range of construction projects.

Fire Safety and Compliance

At the heart of the Class A1 Rail System’s design is its unwavering commitment to fire safety. Achieving a Class A1 fire rating according to EN 13501-1:2018, this system stands as a testament to Wallbarn’s dedication to producing materials that meet the most stringent fire safety standards. This classification ensures that the system is non-combustible, providing peace of mind for builders and occupants alike.

The system’s compliance with BS 8579 further underscores its suitability for use in high-risk areas such as balconies, terraces, and flat roofs. This adherence to British Standards demonstrates Wallbarn’s commitment to producing solutions that not only meet but exceed regulatory requirements, ensuring that projects utilising this system are fully compliant with current building regulations.

Material Composition and Durability

Constructed entirely from metal components, the Class A1 Rail System eliminates the need for plastic or rubber elements, which can compromise fire safety and long-term durability. This all-metal construction not only enhances the system’s fire resistance but also contributes to its exceptional longevity and stability.

The use of high-quality aluminium for the rails and steel for other components ensures that the system can withstand harsh environmental conditions without degradation. Unlike traditional wooden substructures, Wallbarn’s metal system is impervious to rot, warping, and rust, guaranteeing consistent performance throughout its lifespan.

Integration and Versatility

One of the standout features of the Class A1 Rail System is its seamless integration with Wallbarn’s MetalPad EX adjustable pedestals. This integration allows for a fully cohesive substructure that can be easily adjusted to accommodate varying height requirements and uneven surfaces.

The system’s versatility is further enhanced by its compatibility with a wide range of decking and paving materials. Whether the project calls for porcelain tiles, natural stone, or composite decking, the Class A1 Rail System provides a stable and adaptable foundation.

Load-Bearing Capacity and Span Capabilities

Engineered for exceptional strength, the Class A1 Rail System boasts impressive load-bearing capabilities. Official testing has demonstrated the system’s ability to support significant weights, making it suitable for both residential and commercial applications where heavy foot traffic or additional loads are expected.

The system’s design allows for greater spans between pedestals compared to traditional substructure solutions. This increased span capability not only reduces the number of pedestals required but also simplifies the installation process and potentially lowers overall project costs.

By combining fire safety, durability, versatility, and superior load-bearing capacity, Wallbarn’s Class A1 Rail System sets a new standard for substructure solutions in the construction industry. Its innovative design addresses the complex needs of modern building projects, providing a foundation that is as reliable as it is adaptable.

The Ultra-Low Height Solution: Pushing Boundaries in Substructure Design

In the realm of construction and renovation, particularly in urban environments, space constraints often present significant challenges. Wallbarn’s Ultra-Low Height Solution emerges as a game-changer, addressing the growing demand for substructure systems that can be implemented in areas with minimal clearance while maintaining structural integrity and functionality.

Innovative Design for Tight Spaces

The Ultra-Low Height Solution is a testament to Wallbarn’s commitment to innovation and problem-solving. Engineered to achieve a remarkably low profile, this system allows for the installation of decking or paving in areas where traditional substructures would be impractical or impossible. With the ability to create a stable platform at heights as low as 30 mm from the floor to the underside of the deck board, this solution opens up new possibilities for architects and builders.

This ultra-slim profile is particularly valuable in retrofit projects, where existing door thresholds, drainage systems, or other fixed elements limit the available height for new installations. By enabling the creation of level surfaces with minimal elevation, the Ultra-Low Height Solution facilitates seamless transitions between indoor and outdoor spaces, enhancing accessibility and aesthetic appeal.

Material Composition and Structural Integrity

Despite its compact design, the Ultra-Low Height Solution does not compromise on strength or durability. Crafted from high-grade materials, including corrosion-resistant aluminium and steel components, this system is built to withstand the rigours of various environments and loading conditions.

The use of precision-engineered components ensures that even at minimal heights, the system provides a stable and level surface capable of supporting significant loads. This structural integrity is crucial for ensuring the longevity and safety of the installed decking or paving, particularly in high-traffic areas or spaces subject to variable weather conditions.

Versatility in Application

One of the key advantages of the Ultra-Low Height Solution is its versatility. This system is adaptable to a wide range of projects, from residential balconies and patios to commercial terraces and rooftop installations. Its compatibility with various decking and paving materials, including timber, composite, porcelain, and natural stone, further enhances its utility across different design schemes.

The system’s flexibility extends to its adjustability, allowing for fine-tuning of height and level to accommodate slight variations in the substrate or to create subtle slopes for drainage purposes. This adaptability ensures that even in challenging installation scenarios, a perfectly level and stable surface can be achieved.

Installation Efficiency and Cost-Effectiveness

Wallbarn’s Ultra-Low Height Solution is designed with efficiency in mind, both in terms of installation and long-term maintenance. The system’s components are engineered for quick and straightforward assembly, reducing installation time and labour costs. This efficiency is particularly valuable in projects with tight deadlines or in situations where minimising disruption is crucial.

Moreover, the durability and low-maintenance nature of the materials used in the Ultra-Low Height Solution contribute to its cost-effectiveness over time. By eliminating the need for frequent repairs or replacements associated with less robust systems, this solution offers long-term value for property owners and managers.

Compliance and Safety Considerations

Despite its compact profile, the Ultra-Low Height Solution does not compromise on safety or regulatory compliance. The system is designed to meet relevant building codes and standards, ensuring that installations are not only functional but also legally compliant. This adherence to safety standards is particularly important in commercial and public spaces where liability concerns are paramount.

Additionally, the system’s design incorporates features that facilitate proper drainage and ventilation, crucial factors in preventing water damage and ensuring the longevity of both the substructure and the overlying decking or paving material.

By addressing the unique challenges posed by low-clearance installations, Wallbarn’s Ultra-Low Height Solution exemplifies the company’s innovative approach to substructure design. This system not only solves practical problems but also expands the creative possibilities for architects and designers, enabling the transformation of previously unusable spaces into functional and attractive areas.

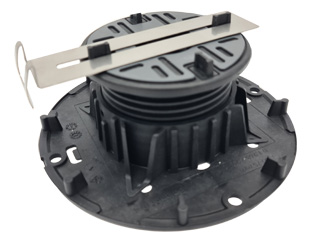

Plastic Pedestal Systems: Balancing Flexibility and Durability

While Wallbarn’s metal-based solutions offer unparalleled fire resistance and strength, the company’s Plastic Pedestal Systems provide an alternative that combines flexibility, cost-effectiveness, and durability for a wide range of applications. These systems demonstrate Wallbarn’s commitment to offering diverse solutions that cater to varying project requirements and budgetary considerations.

Material Innovation and Performance

Wallbarn’s Plastic Pedestal Systems are crafted from high-quality, engineered polymers that offer exceptional strength-to-weight ratios. These materials are carefully selected for their ability to withstand environmental stressors, including UV radiation, temperature fluctuations, and moisture exposure, ensuring long-term performance in outdoor settings.

The use of advanced plastics allows for the creation of pedestals that are not only robust but also lightweight, facilitating easier handling and installation. This combination of strength and lightness contributes to the overall efficiency of construction projects, reducing labour costs and minimising strain on workers during the installation process.

Adjustability and Precision

One of the standout features of Wallbarn’s Plastic Pedestal Systems is their high degree of adjustability. Designed to accommodate a wide range of height requirements, these pedestals can be fine-tuned to create perfectly level surfaces even on substrates with significant variations or slopes.

The precision adjustment mechanisms incorporated into these pedestals allow for millimetre-accurate height settings, ensuring a smooth and even finish for the overlying decking or paving. This level of control is particularly valuable in projects where achieving a seamless transition between indoor and outdoor spaces is crucial, or where specific drainage gradients need to be maintained.

Load-Bearing Capacity and Stability

Despite their lightweight construction, Wallbarn’s Plastic Pedestal Systems boast impressive load-bearing capabilities. Rigorous testing has demonstrated their ability to support substantial weights, making them suitable for both residential and light commercial applications.

The design of these pedestals incorporates features that enhance stability and distribute loads evenly across the substructure. Wide base plates increase the contact area with the substrate, while specially engineered tops provide secure support for joists or pavers. This thoughtful design ensures that the finished surface remains stable and level, even under dynamic loads or in areas subject to frequent foot traffic.

Versatility in Application

The flexibility of Wallbarn’s Plastic Pedestal Systems extends to their compatibility with a wide range of decking and paving materials. Whether supporting timber decking, composite boards, porcelain tiles, or natural stone pavers, these pedestals provide a versatile foundation that can adapt to various design requirements.

This versatility is further enhanced by the availability of different pedestal models and accessories within the range. From ultra-low height options for threshold transitions to taller variants for creating raised decks or hiding services, the system can be tailored to meet the specific needs of each project.

Environmental Considerations

In line with Wallbarn’s commitment to sustainability, the Plastic Pedestal Systems are designed with environmental impact in mind. The materials used are selected for their durability and longevity, reducing the need for frequent replacements and minimising waste over time.

Furthermore, many components of these systems are recyclable, aligning with circular economy principles and contributing to more sustainable construction practices. This focus on environmental responsibility extends to the manufacturing process, where efforts are made to minimise energy consumption and reduce the carbon footprint of production.

Installation Efficiency and Cost-Effectiveness

The design of Wallbarn’s Plastic Pedestal Systems prioritises ease of installation, contributing to overall project efficiency. The lightweight nature of the components, coupled with their intuitive assembly process, allows for rapid deployment on site. This efficiency not only reduces installation times but also contributes to cost savings in terms of labour and project duration.

The durability and low-maintenance requirements of these systems further enhance their cost-effectiveness over the lifespan of the installation. By resisting degradation from environmental factors and requiring minimal upkeep, these pedestals offer a long-term solution that provides value for property owners and managers.

Wallbarn’s Plastic Pedestal Systems represent a thoughtful balance between performance, flexibility, and cost-effectiveness. By offering a range of options within this category, Wallbarn ensures that builders and designers have access to solutions that can meet diverse project requirements while maintaining high standards of quality and durability. These systems exemplify Wallbarn’s commitment to innovation and customer-focused design in the realm of substructure solutions.

Enhancing Lateral Stability: The Role of Integrated Rail Systems

One of the key challenges in creating durable and safe outdoor surfaces is ensuring lateral stability across the entire deck or paved area. Wallbarn’s Integrated Rail Systems address this crucial aspect of substructure design, offering a solution that significantly enhances the overall stability and longevity of installations.

The Importance of Lateral Stability

Lateral stability in decking and paving installations is essential for preventing movement, shifting, or warping of the surface over time. This stability is particularly crucial in areas subject to variable weather conditions, temperature fluctuations, or dynamic loads. By minimising lateral movement, a well-designed substructure system can extend the lifespan of the installation, reduce maintenance requirements, and enhance safety for users.

Design Principles of Wallbarn’s Integrated Rail Systems

Wallbarn’s Integrated Rail Systems are engineered based on the principle of creating a cohesive network that links individual pedestals and supports. This interconnected structure distributes forces more evenly across the entire substructure, significantly reducing the risk of localised stress or movement.

The system utilises specially designed aluminium rails that securely connect to the pedestals, forming a rigid framework. These rails not only provide support for the decking or paving material but also act as structural elements that enhance the overall stability of the installation.

Material Selection and Performance

The choice of materials for the Integrated Rail Systems reflects Wallbarn’s commitment to durability and performance. High-grade aluminium is used for the rails, offering an optimal balance of strength, weight, and corrosion resistance. This material choice ensures that the system can withstand harsh outdoor conditions without degradation, maintaining its structural integrity over time.

The aluminium rails are designed with specific profiles that enhance their strength-to-weight ratio, allowing for longer spans between supports without compromising stability. This design feature not only contributes to the system’s performance but also offers practical benefits in terms of installation flexibility and potential cost savings.

Integration with Pedestal Systems

A key feature of Wallbarn’s Integrated Rail Systems is their seamless compatibility with the company’s range of pedestals, including both metal and plastic variants. This integration is achieved through specially designed connectors and clips that ensure a secure and precise fit between rails and pedestals.

The system’s design allows for easy adjustment and alignment, enabling installers to create perfectly level surfaces even on challenging substrates. This adjustability, combined with the inherent stability of the integrated structure, results in a substructure that can adapt to various site conditions while maintaining optimal performance.

Enhanced Load Distribution

One of the primary benefits of the Integrated Rail Systems is their ability to distribute loads more effectively across the entire substructure. By creating a network of interconnected supports, the system reduces the point loads on individual pedestals, allowing for potentially greater spans between supports and enhancing the overall load-bearing capacity of the installation.

This improved load distribution is particularly valuable in commercial or high-traffic areas where the substructure may be subject to significant and variable loads. The system’s ability to handle these demands contributes to the longevity and safety of the finished surface.

Versatility in Application

Wallbarn’s Integrated Rail Systems are designed to accommodate a wide range of decking and paving materials, from timber and composite decking to porcelain tiles and natural stone. This versatility makes the system suitable for various project types, from residential balconies and terraces to commercial rooftop installations and public spaces.

The system’s flexibility extends to its ability to handle different height requirements and surface designs. Whether creating a single-level deck or a multi-tiered outdoor space, the Integrated Rail Systems can be configured to meet specific project needs while maintaining optimal stability and performance.

Installation Efficiency and Precision

The design of the Integrated Rail Systems prioritises ease of installation and precision. The components are engineered for straightforward assembly, with clear connection points and intuitive adjustment mechanisms. This focus on installation efficiency not only reduces on-site labour time but also minimises the risk of errors that could compromise the system’s performance.

The precision afforded by the rail system allows for the creation of exceptionally level and stable surfaces. This is particularly important for installations using large format tiles or pavers, where even minor discrepancies in level can be noticeable and potentially hazardous.

Long-Term Performance and Maintenance

By enhancing lateral stability and improving load distribution, Wallbarn’s Integrated Rail Systems contribute significantly to the long-term performance of decking and paving installations. The reduced movement and stress on individual components translate to lower maintenance requirements and a decreased likelihood of issues such as loose tiles, uneven surfaces, or structural degradation over time.

The system’s durable materials and corrosion-resistant design further ensure that it maintains its performance characteristics throughout its lifespan, providing a reliable foundation for the overlying surface materials.

Wallbarn’s Integrated Rail Systems represent a sophisticated approach to enhancing lateral stability in substructure design. By creating a cohesive network of supports and distributing loads more effectively, these systems offer a solution that not only improves the immediate performance of decking and paving installations but also contributes to their long-term durability and safety. This innovative approach underscores Wallbarn’s commitment to addressing the complex challenges faced in modern construction and landscape design projects.

Maximising Efficiency: Installation Techniques and Best Practices

The effectiveness of any substructure system is not solely determined by its design and materials but also by the quality of its installation. Wallbarn’s commitment to providing comprehensive solutions extends beyond product development to include guidance on installation techniques and best practices. This focus on installation efficiency and precision ensures that the full potential of their substructure systems is realised in every project.

Preparation and Planning

The foundation of an efficient installation process lies in thorough preparation and planning. Wallbarn emphasises the importance of site assessment and accurate measurements before commencing installation. This preparatory phase includes:

- Evaluating the substrate condition and identifying any potential issues that may affect the installation.

- Determining the required finished height and any necessary gradients for drainage.

- Calculating the number and placement of pedestals and rails based on the specific load requirements and surface material specifications.

- Ensuring all necessary tools and components are on-site and readily accessible.

By investing time in this initial planning stage, installers can significantly streamline the installation process, reducing the likelihood of delays or errors during construction.

Pedestal Placement and Adjustment

Proper pedestal placement is crucial for creating a stable and level substructure. Wallbarn recommends starting with corner and perimeter pedestals, using these as reference points for aligning the rest of the system. Key considerations include:

- Using laser levels or string lines to ensure accurate height settings across the installation area.

- Adjusting pedestals to accommodate any variations in the substrate, ensuring a perfectly level surface.

- Paying particular attention to load-bearing points and areas subject to higher stress, such as corners and edges.

The adjustability features of Wallbarn’s pedestals, including both the Class A1 metal systems and plastic variants, allow for precise height settings. Installers are encouraged to make use of these adjustment mechanisms to achieve optimal levelling, even on challenging substrates.

Rail System Integration

For installations utilising Wallbarn’s Integrated Rail Systems, proper alignment and connection of rails to pedestals are essential for maximising lateral stability. Best practices include:

- Ensuring rails are securely fastened to pedestals using the provided connectors or clips.

- Maintaining consistent spacing between rails as specified for the particular decking or paving material being used.

- Using rail-to-rail connectors where necessary to create a continuous support structure across larger areas.

The integration of rails not only enhances stability but also provides a guide for the placement of subsequent pedestals, contributing to the overall efficiency of the installation process.

Load Distribution and Support

Proper load distribution is critical for the long-term performance of the substructure. Wallbarn provides guidance on optimal pedestal spacing and rail placement based on the specific load requirements of different projects. Key considerations include:

- Adhering to recommended maximum spans between pedestals based on the chosen rail height and expected loads.

- Providing additional support in high-traffic areas or where heavy fixtures will be placed.

- Ensuring even distribution of load across the entire substructure to prevent localised stress points.

By following these guidelines, installers can create a substructure that effectively manages both static and dynamic loads, enhancing the durability and safety of the finished surface.

Surface Material Installation

The final stage of installation involves laying the decking or paving material atop the prepared substructure. Wallbarn’s systems are designed to accommodate a wide range of surface materials, each with its specific installation requirements. General best practices include:

- Using appropriate spacers or clips to maintain consistent gaps between decking boards or tiles.

- Ensuring proper alignment of surface materials with the underlying support structure.

- Following manufacturer guidelines for the specific decking or paving product being used.

The precision and stability provided by Wallbarn’s substructure systems facilitate a smoother and more accurate installation of the surface material, contributing to a higher quality finished product.

Quality Control and Final Adjustments

Throughout the installation process, and particularly upon completion, thorough quality control checks are essential. These checks should include:

- Verifying the levelness of the surface across the entire installation area.

- Ensuring all components are securely fastened and correctly positioned.

- Testing the stability of the surface under various load conditions.

Wallbarn’s systems allow for fine adjustments even after the initial installation, enabling installers to address any minor discrepancies identified during these final checks.

Safety Considerations

Safety is paramount throughout the installation process. Wallbarn emphasises the importance of adhering to all relevant safety guidelines and regulations, including:

- Proper use of personal protective equipment (PPE).

- Safe handling and transportation of materials and tools.

- Adherence to height safety protocols for elevated installations.

By prioritising safety, installers not only protect themselves but also contribute to the overall integrity and reliability of the finished installation.

Ongoing Maintenance and Inspection

While Wallbarn’s substructure systems are designed for durability and low maintenance, regular inspections and maintenance can further extend their lifespan. Recommendations include:

- Periodic checks for any signs of movement or wear.

- Cleaning of drainage channels to ensure proper water flow.

- Retightening of any loose components as needed.

By implementing these maintenance practices, property owners and managers can ensure the continued performance and safety of their decking or paving installations.

Wallbarn’s approach to installation efficiency and best practices reflects their commitment to delivering comprehensive solutions that extend beyond the product itself. By providing detailed guidance and emphasising the importance of proper installation techniques, Wallbarn ensures that their substructure systems perform optimally in real-world applications. This focus on installation quality not only enhances the immediate success of projects but also contributes to the long-term satisfaction of end-users and the reputation of the construction professionals who implement these systems.

Compliance and Certification: Meeting Industry Standards

In an industry where safety, quality, and regulatory compliance are paramount, Wallbarn’s commitment to meeting and exceeding industry standards sets their substructure systems apart. This dedication to compliance and certification not only ensures the reliability and performance of their products but also provides peace of mind for architects, contractors, and property owners.

Fire Safety Compliance

One of the most critical aspects of compliance for building materials, especially in light of recent regulatory changes, is fire safety. Wallbarn’s Class A1 Rail System exemplifies the company’s commitment to this crucial area:

- Certified to EN 13501-1:2018 with a Class A1 fire rating, the highest possible classification for non-combustibility.

- Fully compliant with BS 8579, which sets standards for the design of balconies and terraces in multi-storey buildings.

This level of fire safety compliance makes Wallbarn’s systems particularly suitable for high-rise buildings and other projects where stringent fire resistance is required. The all-metal construction of these systems eliminates the use of plastic or rubber components that could compromise fire safety.

Load Bearing and Structural Integrity

Wallbarn’s substructure systems undergo rigorous testing to ensure they meet or exceed load-bearing requirements:

- Official test reports document the systems’ ability to withstand significant loads, with break points far exceeding typical usage scenarios.

- Compliance with relevant structural engineering standards ensures the systems can support the intended loads safely over time.

These certifications provide confidence in the structural integrity of installations, particularly important for commercial and public spaces where safety and liability are key concerns.

Environmental Management and Sustainability

Wallbarn’s commitment to environmental responsibility is reflected in their certifications:

- ISO 14001 Environmental Management Systems certification demonstrates the company’s systematic approach to managing environmental impacts.

- Use of recyclable materials and consideration of lifecycle impacts in product design align with broader sustainability goals in the construction industry.

These environmental credentials are increasingly important as the industry moves towards more sustainable building practices and as clients seek environmentally responsible solutions.

Quality Management Systems

The consistency and reliability of Wallbarn’s products are underpinned by robust quality management processes:

- ISO 9001 Quality Management certification ensures that all aspects of product development, manufacturing, and delivery adhere to internationally recognised standards.

- Regular audits and continuous improvement processes maintain the high quality of Wallbarn’s substructure systems over time.

This commitment to quality management provides assurance to clients that they are receiving products of consistent high quality, regardless of project scale or location.

Compliance with Building Regulations

Wallbarn’s systems are designed with full awareness of current building regulations:

- Compliance with relevant parts of the Building Regulations, including those related to structure, fire safety, and accessibility.

- Regular updates to product specifications and guidance to reflect changes in regulatory requirements.

This proactive approach to regulatory compliance ensures that projects utilising Wallbarn’s systems can meet necessary legal and safety standards without additional modifications or concerns.

Product-Specific Certifications

In addition to overarching compliance standards, Wallbarn provides product-specific certifications:

- Load Tolerance Test Certificates for individual components and assembled systems.

- Material composition certifications, particularly important for the Class A1 systems where material purity is crucial for fire safety.

These detailed certifications allow specifiers and installers to select the most appropriate systems for their specific project requirements with confidence.

Accessibility and Inclusivity Standards

Wallbarn’s substructure systems, particularly the ultra-low height solutions, are designed with consideration for accessibility standards:

- Compliance with regulations regarding level thresholds and smooth transitions between indoor and outdoor spaces.

- Ability to create surfaces that meet slip resistance requirements for public and commercial spaces.

This focus on accessibility ensures that installations can meet the needs of all users, including those with mobility challenges.

Durability and Longevity Testing

The long-term performance of Wallbarn’s systems is backed by extensive durability testing:

- Exposure tests to simulate various environmental conditions, including UV radiation, moisture, and temperature fluctuations.

- Cyclic load testing to ensure sustained performance under repeated stress.

These tests provide assurance of the systems’ ability to maintain their structural integrity and functionality over extended periods, even in challenging environments.

Compatibility with Other Building Systems

Wallbarn ensures that their substructure systems are compatible with a wide range of building systems and materials:

- Testing and certification of compatibility with various decking and paving materials.

- Consideration of integration with other building elements such as drainage systems, insulation, and waterproofing membranes.

This comprehensive approach to compatibility simplifies the specification process and reduces the risk of conflicts between different building components.

Ongoing Compliance and Certification

Wallbarn’s commitment to compliance and certification is an ongoing process:

- Regular review and updating of certifications to reflect the latest industry standards and regulatory requirements.

- Participation in industry bodies and standards committees to stay at the forefront of developments in building technology and safety.

This proactive stance ensures that Wallbarn’s products remain compliant and certified even as industry standards evolve.

Wallbarn’s comprehensive approach to compliance and certification demonstrates their commitment to providing substructure solutions that not only perform exceptionally but also meet the highest standards of safety, quality, and regulatory compliance. This dedication provides significant value to all stakeholders in the construction process, from architects and specifiers to contractors and end-users. By choosing Wallbarn’s certified systems, projects can benefit from the assurance of compliance with current standards, potentially streamlining approval processes and reducing long-term risks associated with non-compliant materials or systems.