Previously, we discussed the difficulty of adapting balconies and terraces with heights over 19m (11m in Scotland) to meet fire safety regulations that prohibit combustible materials on tall buildings.

Without practical knowledge, it is hard to determine what is beneath decking or paving until it is uncovered, making it difficult to determine, detail and cost the installation accurately.

A noteworthy project recently completed was the overhaul of a London penthouse terrace. The decking system used had to be Class A fire-rated. After removing the installed timber decking with timber bearers, the underlying roof deck was found to have multiple uneven levels and sudden rises.

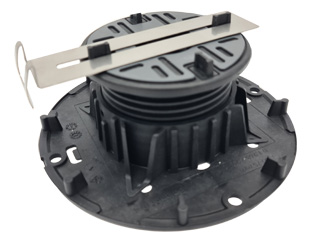

A complex substructure was necessary in order to retrofit the chosen, top-quality Exadeck porcelain and Wallbarn products were employed for this purpose. The frame was put together with MetalPad D adjustable height pedestals, connected to aluminium rails/joists. Box rails and I-Plus beams were employed due to the different height levels.

In certain locations, 20mm box rails were secured in place with the lowest height pedestals, whereas in other areas, the 100mm I-Plus beam was doubled and affixed to itself. To achieve an even level, these were mounted onto larger MetalPad D pedestals.

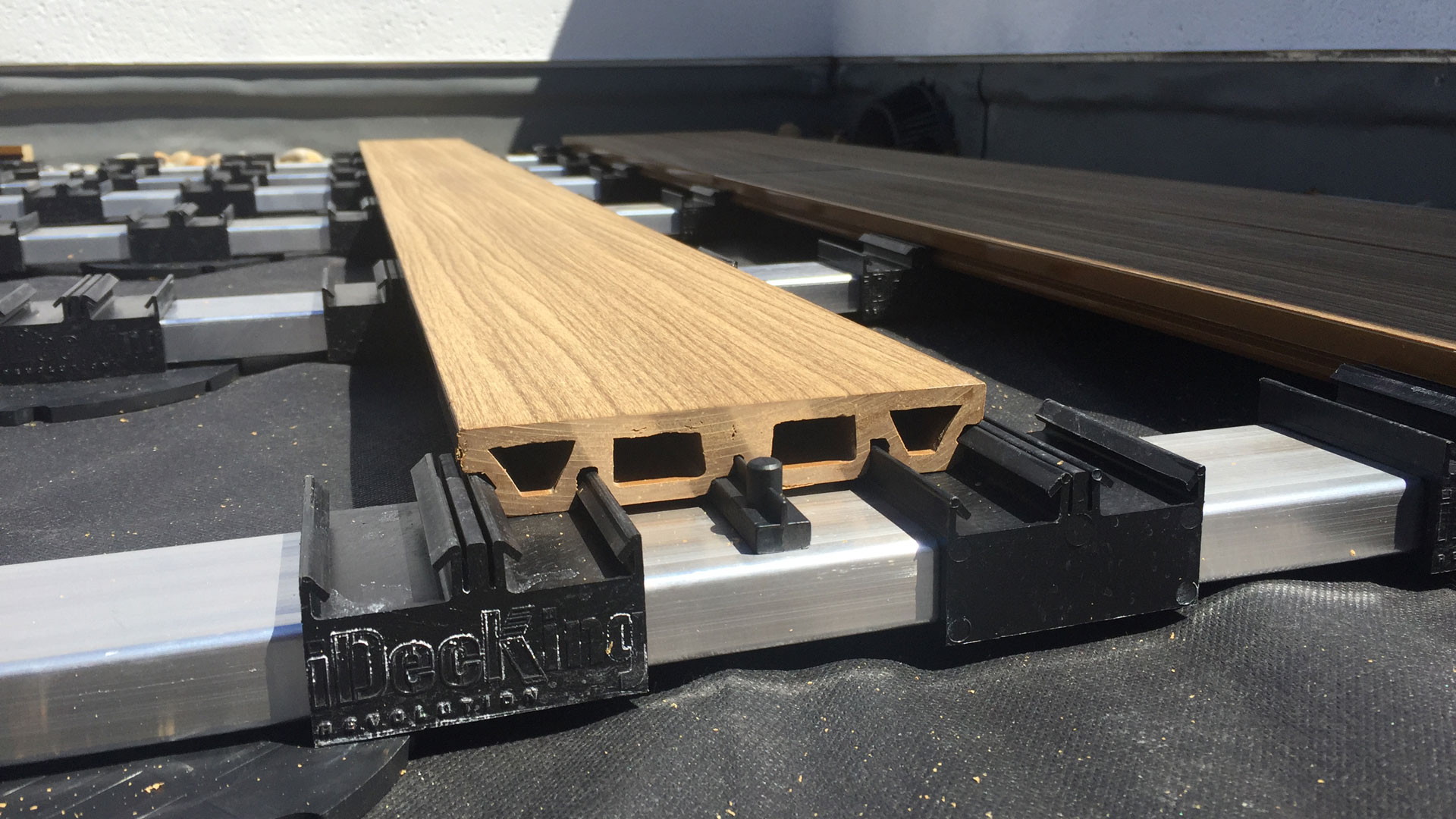

Making the project more complex, the deckboards had to be placed at a diagonal angle to the building, so the upper level of aluminium rails had to be affixed to this incline in order for the decking clips to be attached in a perpendicular direction to the rails. Connector brackets were utilized to provide additional structural integrity and stability where the rails met.

Exadeck’s design permits the installation of invisible fasteners to hold the boards securely and to establish a consistent spacing between them for draining purposes.

During the manufacturing process, the boards are made to be perfectly flat in all planes, with no risk of them curling, bending, or altering in width and thickness. Additionally, the bottom side is flat as well, allowing them to be placed securely on the rail surface without any rocking.

Complex Subsection

The undertaking was challenging and the contractor was unable to check out what was beneath the current timber deck before the job commenced. As no detailed plans were available, the exact height limits and other technical specs were not known. When they removed the timber decking, they discovered an intricate substructure with considerable variations in depth. The terrace itself had curves, peculiar angles, and several upstands and pillars, making the height of the pedestals and rails necessary to create a smooth decking surface vary significantly.

Wallbarn’s designers created a finished plan for the terrace which included MetalPad D pedestals that were adjustable and linked to I-Plus beams and double box aluminium rails.

The upstands and pillars posed a considerable hurdle in terms of the altitude limits. To tackle this, Wallbarn used the shortest pedestals available at 25-32mm, securing them to a 20mm and 25mm double box rail. In the vicinity of these structures, the company employed its 100mm I-Plus rail, mounted on taller MetalPad D pedestals. For extra stability, these pedestals were sometimes stacked and fixed to each other in multiple layers.

The combination of MetalPad D, I-Plus, and double box rails provided a great benefit; the shape of the rails was ideal for slotting in between the lugs on the pedestal headpiece, meaning that extra mechanical fixing was not required to make sure the rails were fixed in place. This design allowed for a degree of flexibility, with the ability for the rails to move slightly for the best performance. This also gave the installation a cleaner look.

Expansion of Ideas and Concepts

The Wallbarn system stands out from other brands in that it minimises the stress points which could cause mechanical fixing points to be pulled out due to the difference in expansion and contraction rates of the structure and decking. This should not be overlooked.

An aluminium rail framework was created with straight and right-angled brackets connecting the rails along straight sections and in the corners. Stainless steel screws were used in the appropriate places.

Wallbarn provided the capability to meet complex demands and deliver a top-notch, fireproof end product due to the range of rail heights and types.