A modular new build house in Sussex had a large flat roof deck above a swimming pool and fitness room which led out from the bedrooms. The client wanted to construct a roof terrace using porcelain tiles, but there was a serious complication.

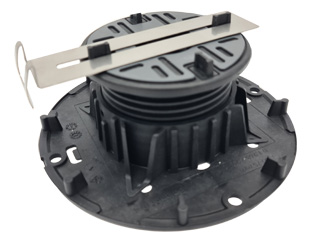

The timber-framed modular building could not support the weight of the steel staircase which was required, so a series of steel braces were constructed across the top of the deck surface to straddle the structure and create a self-supporting staircase. This left the roof space with a number of large impediments, making laying a tiled terrace extremely difficult. They opted for the Rail System from Wallbarn to incorporate adjustable height pedestals which click into a series of aluminium rails, with an independent top headpiece to hold the tiles in place.

It was impossible to lay pedestals every 400 x 800mm (the dimensions of the tiles) as they would have hit the steel braces, so Wallbarn designed a scheme where the pedestals would be laid up to the height of the braces but away from them and the rails would span over the braces. The rail is profiled so it clicks into place on the headpiece of the pedestal without mechanical fixings. This means any expansion movement etc. can be accommodated without screws erupting from the system over time.

The height of the pedestals was adjusted by twisting the stems, so the falling roof deck was able to be laid flat. The rail itself can be used as an aid to obtain the correct height level across the deck. Millimetre precise adjustments can be set the optimum surface level to door thresholds and access points. If there were any sections where a pedestal could be placed, the hazard could be spanned by laying the rail across it, so long as the rail is supported at each end any awkward deck objects can be avoided.

Wallbarn recommends a maximum span of 600mm between pedestals and rails. The top head was clicked onto the profiled rail and could be slid along so to match the dimensions of the tiles. The headpieces could thus be exactly underneath the corners of each tile without the tile being cut to fit around the steel braces. So although the pedestals had to be placed around the braces, the porcelain tiles were suspended over the braces completely unaffected.

The lateral stability of the tiled area is improved greatly as the pedestals are connected to each other via the rail which also acts as a balancing tool. The whole system is tied together. No mechanical fixings go through the deck surface, the whole system is free standing. The weight of the tiles holds everything in place.

The tiles were laid quickly and securely. They were held in position in the long term, creating a solid, stable upper surface. This suspension system creates a superior finish. The joints between each tile are smooth and it gives a higher performance deck area. A high quality, sturdy and very attractive porcelain tiled terrace was created quickly with no mess and waste. The client was delighted.

For the full article, please click here.