We were recently called in to help complete a refurbishment project in Bermondsey, SE1 which involved us acting in the role of advisor to the main contractor as they worked towards resurfacing the flat roof at the top of the school for the pupils to use as a play / outdoor classroom.

The main contractor was Kier Services – Facilities Management and the sub-contractor, who called Wallbarn in for advice, was PM Associates.

Working To a Tight Schedule

The time schedule for the project was extremely tight with the roof needing to be re-waterproofed and covered with the hard landscaping in the one-week window of the half-term break.

The roof deck was built to a fall to allow adequate drainage off the surface, the overall fall across the 10 metre length was approx. 100mm. Access to the roof area was very restricted.

Working with no crane resulted in all of the products having to be handballed up five flights of a very tight, Victorian staircase. Handballing 3 metre lengths of timber decking boards and softwood substructure was impossible.

Suggested Materials

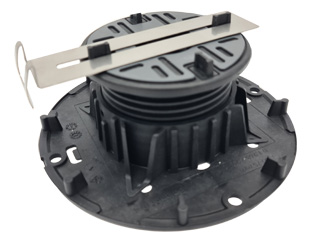

We suggested using IPE hardwood timber tiles – 500 x 500mm x 30mm in size – mounted onto ASP adjustable pedestals. This would allow the decking surface to be laid to flat, creating a better finish for the pupils and teachers.

Wallbarn delivered the materials to site and everything was carried up the stairs to the roof area. Laying the decking boards onto the ASP pedestals meant that no fixings had to be made through the waterproofing membrane. This meant that the waterproofing seam was not punctured, which avoided the risk of leaks and meant none of the warranties were compromised. Installation of also extremely fast and simple.

Installation Techniques

The tiles were lined up at the highest point of the roof mounted onto fixed height 7mm rubber pads and levelling shims, and as each row of tiles was installed, gradually higher and higher pads and pedestals were laid under them to create a flat upper surface.

Half of the roof was laid with tiles, the other half with artificial grass. The junction between the grass and the tiles was fitted with an angled rubber fillet to prevent the tiles moving over time.

Exceptional Resolution

The installers were very pleased with the speed and ease of the system, and the project was finished in time and within budget. The end result was an extremely attractive finish. The client was delighted with the result.

The following gallery highlights some the changes that took place during the completion of the project.