Meticulously engineered to meet the stringent British building regulation standards BS 8579:2020 for balconies and terraces, the innovative CDeck cement fibre comprehensive decking system boasts unrivalled strength and resilience. Its unique composition ensures that it will not succumb to the ravages of fire, rot, rust, or warping, making it an exceptional choice for both residential and commercial applications.

Exceptional Performance Characteristics

The CDeck cement fibre full decking system is a true testament to superior craftsmanship and cutting-edge technology. Its high-density inorganic fibre cement boards, reinforced with a crystal structure of tobermorite, exhibit remarkable flexural strength, surpassing the industry benchmark of 13MPa. This exceptional strength translates into a robust decking surface capable of withstanding substantial weight loads, making it an ideal solution for high-traffic areas and public spaces.

Moreover, the system’s non-combustible nature, achieving the highest fire resistance classification of A1 under GB8624-2012, guarantees utmost safety and peace of mind. Its weather-resistant properties have been rigorously tested, enduring 100 freeze-thaw cycles, 50 hot rain cycles, and a 56-day hot water immersion test, ensuring its suitability for even the harshest climatic conditions.

Environmental Stewardship and Energy Efficiency

Beyond its structural prowess, the CDeck cement fibre decking system embraces a comprehensive approach to sustainability. It meets the stringent requirements for Class A decorative materials, ensuring a safe and healthy living environment The raw materials – wood pulp, cement and quartz mineral dust are all 100% recyclable, so it underscores the system’s commitment to minimising its environmental impact.

Complementing its eco-friendly credentials, the system’s energy-efficient design contributes to reducing overall energy consumption, aligning with global efforts to mitigate climate change. By prioritising environmental stewardship, the CDeck cement fibre decking system sets a new standard for responsible outdoor construction.

Aesthetic Versatility and Slip Resistance

While functionality remains at the forefront, the CDeck cement fibre decking system does not compromise on aesthetic appeal. Its high-density composition and anti-slip properties ensure a visually stunning yet safe surface, perfect for outdoor living spaces. Whether you envision a sleek and modern design or a more rustic, natural wood grain appearance, the system’s versatility allows you to seamlessly integrate it into your desired architectural style.

Independent Testing and Certifications

To validate its exceptional performance, the CDeck cement fibre decking system has undergone rigorous testing during manufacture to ensure long-term performance.

Long-term durability and slip resistance is assured so users can be confident that this comprehensive decking system meets the test of time and traffic.

Comprehensive System Components

The CDeck cement fibre decking system comprises a comprehensive range of support structure components, each meticulously designed to work in harmony, ensuring seamless installation and optimal performance. From the aluminium box rails and I-Plus joists to the MetalPad Ex pedestals and W Clip hidden deck fixings, every element has been rigorously tested and certified for fire resistance, weight tolerance, and durability.

Aluminium Box Rails and I-Plus Joists

At the heart of the system lie the aluminium box rails and I-Plus joists, engineered to achieve extensive spans while being lightweight and easy to install. Crafted from high-quality 6063 T6 aluminium, these components boast a Class A1 fire classification under BS EN 13501-1 2018, ensuring uncompromising safety.

The box rails and I-Plus joists have undergone independent testing by STS-Group, determining their maximum weight-bearing capacity and recommended pedestal placement.. The testing, conducted in accordance with BS 8579:2020 and BS 8527:2020, targeted specific load thresholds resulting in a 5mm deflection. The results confirmed the rails’ ability to withstand substantial weights.

This meticulous evaluation ensures an even distribution of weight, minimising point loading and maximising the system’s longevity.

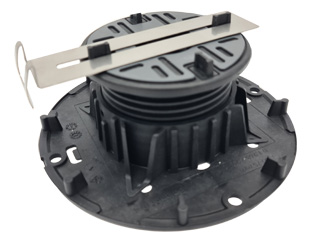

MetalPad Ex Pedestals and Spreader Plates

Complementing the aluminium rails and joists, the MetalPad Ex pedestals and spreader plates play a crucial role in the system’s overall performance. Constructed from mild steel and coated with Zintec 200 fire-proof and anti-corrosion protection, these support pedestals are specifically designed for use in external applications while maintaining their structural integrity. They will not corrode in wet or damp weather.

The spreader plates, in particular, are engineered to disperse weight evenly, reducing point loading on vulnerable surfaces such as insulation or waterproof membranes. This attention to detail means that the decking system can be used on a large variety of different underlying surfaces, enhancing its versatility. Using spreader plates also increases the overall weight tolerance and stability of the pedestals (from approx. 5 tonnes to over 7 tonnes) themselves.

Concealed Fixing Solutions

Recognising the importance of aesthetics, the CDeck cement fibre decking system incorporates innovative concealed fixing solutions. The W Clip hidden deck fixing system has been specially designed to hold the boards securely and crucially dead flat on the rails, and also allow for a sleek and seamless installation. W Clip is supplied with the screws already partially installed into the holes. This avoids the screws popping out during the installation process and speeds up fixing immensely. It is important to use the Red Jig to drill pilot holes of 3mm diameter with a titanium-tipped drill bit for best results. , The gap between the boards is 5-6mm wide, giving a tight and luxurious finish and enhancing the visual appeal of the decking surface.

Installation and Maintenance Simplicity

While the CDeck cement fibre decking system boasts exceptional technical capabilities, its installation and maintenance processes are remarkably straightforward. Comprehensive installation guides and technical datasheets provide clear instructions, ensuring a smooth and efficient installation process, even for complex projects.

Maintenance is equally hassle-free, with regular cleaning and periodic inspections being the primary requirements. The boards will require re-application of a sealant approximately every 5 years. The system’s robust construction and resistance to various environmental factors minimise the need for extensive upkeep, allowing you to enjoy your outdoor space with minimal effort.

Cutting and Drilling Precision

To ensure precise and safe cutting and drilling of the system components, it is recommended to utilise premium blades and tools specifically designed for metal and cement fibre board applications. These specialised tools minimise the production of particles and sparks, reducing potential hazards and ensuring a clean, accurate cut every time.

Proper protective equipment, including eye protection, gloves, and respiratory masks, should be worn during the cutting and drilling processes to mitigate any associated risks.

Comprehensive Warranty and Expected Lifespan

Wallbarn Ltd, the supplier of the CDeck cement fibre decking system, stands behind its products with a comprehensive limited warranty of 15 years. This warranty covers material defects, cracking, splintering, swelling, rot, and structural damage caused by damp or fungal decay, provided that the system is installed and maintained according to the manufacturer’s guidelines.

Moreover, the expected lifespan of the CDeck cement fibre decking system is an impressive 50 years, further solidifying its position as a long-term investment in outdoor living spaces.

Conclusion

The CDeck cement fibre comprehensive decking system represents a paradigm shift in outdoor construction, combining unparalleled strength, durability, and environmental responsibility. With its exceptional performance characteristics, versatile aesthetic appeal, and comprehensive range of components, this innovative system redefines the boundaries of outdoor living spaces.

Whether you are a homeowner seeking to enhance your backyard oasis or a commercial developer envisioning a stunning public and fire-safe space, the CDeck cement fibre comprehensive decking system offers a future-proof solution that transcends the limitations of traditional decking materials.

Embrace the cutting-edge of outdoor construction and experience the unrivalled quality, safety, and longevity that the CDeck cement fibre decking system promises.