We’ve spoken previously about the difficulties retrofitting at-height balconies and terraces to bring them into line with fire safety regulations banning combustible materials on high rise buildings above 19m (11m in Scotland).

From experience, we know that you cannot be sure of what lies beneath decking or paving until it is lifted, making it difficult to accurately assess, specify and cost installations.

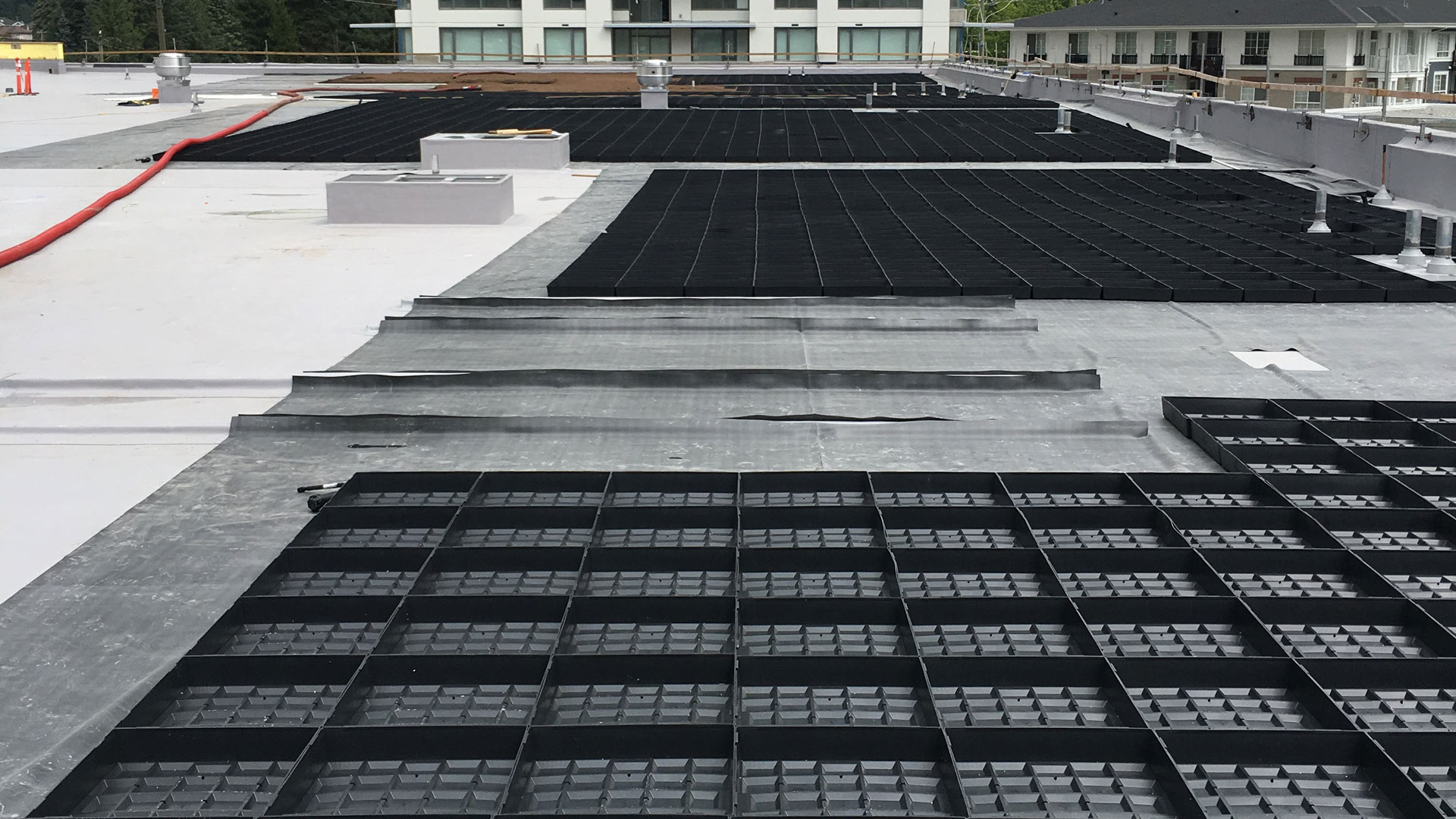

A recent project – the refurbishment of a London duplex penthouse apartment terrace with a Class A fire-rated decking system – is a case in point. The removal of timber decking mounted on timber bearers revealed a roof deck with multiple levels and unexpected upstands.

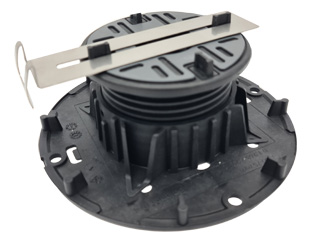

The retrofit therefore required a complex substructure utilising a range of Wallbarn products into which the selected high-quality Exadeck porcelain could be laid. The substructure frame was formed from Wallbarn MetalPad D adjustable height pedestals fitted to its aluminium rails/joists. Both box rails and I-Plus beams were used due to the varied height thresholds.

The lowest height pedestals were fitted to 20mm box rails, whilst in other areas the 100mm high I-Plus beam was doubled up and fitted to itself. These were then mounted onto larger MetalPad D pedestals in order to create a consistent level.

To complicate the project, the deckboards were to be laid on a diagonal plane to the build so the top layer of aluminium rails needed fixing on this angle to allow decking fixing clips to be mounted at right angles to the rails. Connector brackets were used where rails met to add structural strength and stability.

Exadeck’s profile allows hidden wing clips to be fitted to hold the boards in place and provide an even drainage gap between each one.

Importantly, the boards are ‘rectified’ during the manufacture to ensure complete flatness, uniformity and straight lines across all planes with no risk of curly, bending or changes in thickness /width. The under surface is also completely flat so they sit securely on the rail surface and do not rock.

Complicated sub-deck

With two levels of terrace to replace, plus a connecting staircase, the project was complex and the contractor to did have the opportunity to inspect beneath the existing timber deck prior to work starting. No drawings were available and the height thresholds / other technical information as not known. Removal of the timber decking revealed a complicated sub-deck which varied greatly in depth. The terrace itself was irregular in shape with curves, awkward angles and a number of upstands / pillars. The height of the pedestals and rails required to create a level decking surface varied enormously.

Wallbarn’s design team produced a complete layout for the terrace incorporating MetalPad D adjustable pedestals connecting to I-Plus beams and double box aluminium rails.

The height thresholds presented a significant challenge along the upstands and pillars. Connectors used the lowest 25-32mm pedestals, fitting them to a 20mm and 25mm double box rail, However, in areas around these structures, Wallbarn deployed its 100mm I-Plus rail installed on taller MetalPad D pedestals. In some instances, these pedestals were doubled up and securely fixed to each other in layers.

Utilising MetalPad D in conjunction with the I-Plus and double box rails offered a distinct advantage; the profiles of these rails fit nearly between the lugs on the pedestal headpiece, ensuring a secure fit without the necessity for the mechanical fixing of the rail. This design allowed the decking system some flexibility, permitting slight movement in the rails for optimal performance. It also spiffed up the installation.

Expansion

As the structure ad decking will expand and contract at different rates it was important that stress points – where mechanical fixing points might be pulled out – were minimised. This is a key distinction of the Wallbarn system over other brands and should not be ignored.

A solid framework of aluminium rails was constructed using straight and right angled brackets to link rails across long straight sections and at corners. Stainless steel screws were used where appropriate.

The variety of rail heights and type meant Wallbarn could accommodate complicated requirements to deliver a high-end, fire-safe finish.