The release of BS 8579:2020 Guide to the Design of Balconies and Terraces is a welcome addition to the Government’s more robust approach to the fire safety of blocks of flats and supports the already-updated Building Regulations and Approved Document B.

The new standard states that all construction elements of balconies and terraces located more than 18m above ground level must be non-combustible, including structural joists, flooring and suspension etc. This means no wood, plastic, rubber etc. Importantly, the regulations now define balconies as part of the external wall, bringing them in scope of Part B and its more stringent fire safety requirements and ending the conflict that specifying to Part L placed upon fire performance.

Balconies have long been considered an important amenity, providing covered walkways or giving residents access to private outside space. Now, more than ever, that amenity is highly prized post-COVID-19 lockdown and it is likely that future new-build developments will be looking to incorporate them.

BS 8579 may be considered one of the regulatory responses to fires in residential multi-storey buildings, including Samuel Garside House, Barking, The Cube in Bolton and Worcester Park, south west London, but work on the standard began two years earlier than these 2019 blazes and several weeks before the Grenfell tragedy.

Social housing providers have taken note, with a number introducing balcony smoking bans (smoking materials, BBQs and arson are the main causes of balcony fires). The Home Group, which supports 125,000 residents nationwide, has produced a ‘Keeping your balcony safe’ leaflet and formed a fire safety tenant focus group.

Back in 2016, the issue was highlighted by the Building Research Establishment’s report – ‘Fire safety issues with balconies’ – compiled for the Department of Communities and Local Government following balcony blazes on high-rise residential buildings in 2010-2015. BRE reported that six balcony ‘fire incidents’ were reported in 2015 compared to one in 2005.

The report makes sobering reading, especially its references to one balcony set alight by a plastic cup used as an ashtray; the block of flats was predominantly a concrete construction with external surfaces “covered in a variety of cladding systems with cavities filled with a variety of rigid foam insulation”. The balcony floor was timber decking on timber battens covered with a woven plastic sheet over foam insulation. The sheet ignited and the fire spread to the foam insulation on the walls and under the decking.

This summer, the insurer Zurich called for balcony BBQs to be banned, stating that almost £9m of damage was caused in 2019 by just four balcony blazes which spread to neighbouring flats or entire buildings. Its research also revealed that in London alone there were 550 balcony fires in the last three years. “Modern methods of construction, including timber-framed buildings, combustible cladding, wooden balconies and modular units add to the risk of balcony fire,” added Zurich.

With the introduction of BS 8579 and the strengthened Building Regulations and Approved Document B banning the use of combustible materials in external wall systems and balconies 18m+, concerns about these construction methods should be answered. We are also seeing increasing numbers of clients opting to implement the new regulations at lower heights to ensure the ongoing safety of residents and assuage insurers rightly concerned about the huge cost to them of fires on balconies.

However, Wallbarn fears that efforts to improve the fire performance of buildings may create a risk that fully tested, established and quality – but not compliant – building solutions may be replaced by seemingly compliant but lower performance products. And that’s why we need to be absolutely sure that the industry is properly briefed to design, specify and build fully compliant and safe solutions.

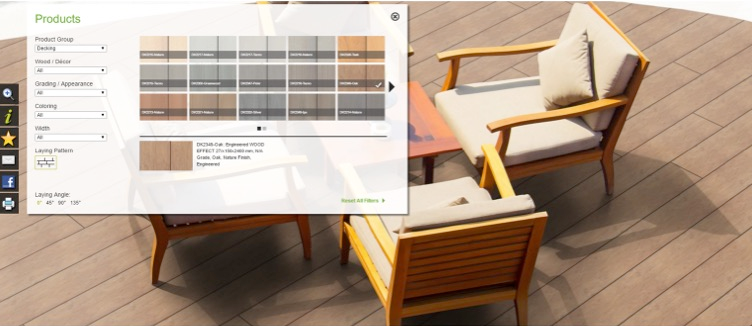

Our sector – pedestal systems which support suspended balcony and terrace decking/paving – is a good example of this. Traditionally, pedestals were heavy-duty polypropylene plastic but to satisfy BS 8579, they will have to be metal when installed at height. These products are available – Wallbarn has developed MetalPad, an all-metal, Class A1-rated pedestal that is fully compliant with BS 8579 – but we know that systems have come to market which have rubber or plastic elements labelled as ‘gaskets’. To call a plastic headpiece a ‘gasket’ does not, in our opinion, conform to the standards and regulations.

We are also concerned about the quality and testing regimes of some metal pedestal solutions. From sampling the market, we know that not all products offer the level of performance we feel is required. Some pedestals have been modified from interior usage and are not designed for exterior applications. The small baseplates on some brands are cutting into surfaces beneath, compromising U-values and creating uneven, unstable paving areas. There is a real risk of jeopardising safety on schemes through the very task of trying to improve fire safety.

There’s also the question of product testing, a crucial factor given these systems are used at-height. Load-bearing is critical and we have heard reports that hollow stems can lead to collapse. Our advice is always to consult with your original supplier to at least understand the questions you should be asking of a new supplier. This is especially important in the light of Grenfell; recent witness evidence at the Grenfell Enquiry has revealed confusion about product performance, suitability and installation methods, highlighting the need for everyone to take responsibility throughout the supply chain. Do not assume someone else is doing it and always ask for – actually demand – test results.

Product provenance is a further issue to be considered. Recent industry talk suggests that imported product was rejected by two main contractors upon arrival at site due to quality concerns. It is good to hear that, despite the inevitable project delays and additional costs such action would have created, quality was considered more important. Again, our advice is to ask the right questions during specification to ensure that the chosen solution is designed for purpose, fully tested and supplied by a trusted partner.

For the full article, please click here.