When it comes to creating a beautiful and long-lasting deck, the quality of decking boards is paramount. An essential factor in determining this quality is the milling process. This intricate procedure transforms raw logs into the smooth, uniform boards that make up the decks in our homes and public spaces. In this blog, we’ll delve into the milling process, exploring how it shapes the quality, durability, and overall performance of decking boards.

The Journey from Log to Decking Board: A Step-by-Step Process

1. Selection and Preparation of Logs

The process begins in the forest, where logs are carefully selected based on wood species, size, and quality. The chosen species often depends on the desired characteristics of the final product, such as hardness, grain pattern, and resistance to decay. Once selected, these logs are cleaned, trimmed, and prepared for sawing, ensuring they are free from defects that could affect the quality of the decking boards.

2. Sawing the Logs

Sawing is the first major step in the transformation process. Logs are cut into rough planks using various methods. Flat sawing produces a plank with a cathedral grain pattern, while quarter sawing results in a more uniform grain and improved stability. The sawing method influences the wood’s appearance and structural properties, playing a crucial role in the board’s final use.

3. Drying the Wood

After sawing, the wood must be dried to reduce its moisture content. This is a critical step, as the right moisture level minimizes the wood’s natural tendency to shrink, swell, or warp. Drying can be achieved through air drying or more controlled methods like kiln drying. The method chosen affects the wood’s stability and is a key factor in ensuring the longevity of the decking boards.

4. Planing and Profiling

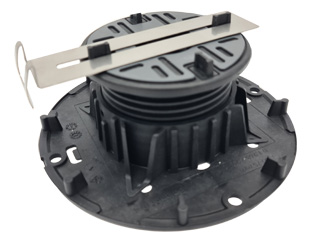

Once dried to the appropriate moisture level, the wood planks are planed. This process smoothens the wood surface and brings the planks to a uniform thickness. The boards are also profiled during this stage, where edges are shaped to specific designs, such as rounded for safety or grooved for hidden fasteners. This step not only affects the board’s aesthetics but also its functionality and ease of installation.

5. Quality Control

Rigorous quality control is essential throughout the milling process. Each board is inspected for defects, uniformity, and proper moisture content. This ensures that only the best-quality boards make it to the market, reducing the likelihood of issues like warping or rotting after installation.

6. Treatment and Finishing

Finally, depending on the end use, the decking boards may undergo additional treatments. Pressure treatment with preservatives can enhance the wood’s resistance to decay, insects, and moisture. Finishing touches like staining or sealing can also be applied, adding colour and extra protection against the elements.

Why is the Milling Process So Important?

- Structural Integrity: A precisely milled decking board ensures uniformity in size and shape, crucial for the structural integrity of the deck. This uniformity provides a stable, even surface, capable of withstanding weight and environmental stresses.

- Aesthetic Appeal: The milling process significantly influences the aesthetic quality of the boards. A well-milled board showcases a beautiful, consistent grain pattern, enhancing the natural charm of the wood.

- Durability and Longevity: Properly milled and dried wood is less prone to issues like warping, splitting, or decay. This extends the lifespan of the deck, ensuring it remains beautiful and functional for years.

- Safety: Milling also involves refining the board edges and surfaces, making them smooth and safe to walk on. This is particularly important in residential settings and public areas.

- Ease of Installation: Uniformly milled boards fit together seamlessly, simplifying the installation process. This uniformity reduces the likelihood of complications during deck construction, saving both time and labour costs.

In conclusion, the milling process is a critical aspect of decking board production. It’s the foundation of a deck’s quality, durability, aesthetic appeal, and safety. Understanding this process helps homeowners and builders alike appreciate the value of high-quality milling and make informed decisions when selecting materials for their decking projects. Remember, a well-milled deck is not just a structure; it’s a long-term investment in the beauty and functionality of your outdoor space.