In an era where safety and sustainability go hand in hand with aesthetic and functional design, the Class A Rail Substructure system stands out as a pioneering solution. Developed to meet the stringent demands of modern exterior paving systems, this product not only ensures robustness and durability but also sets new standards in fire safety. Let’s delve into the myriad of features and benefits that this innovative system brings to the table.

A Harmonious Blend of Safety and Stability

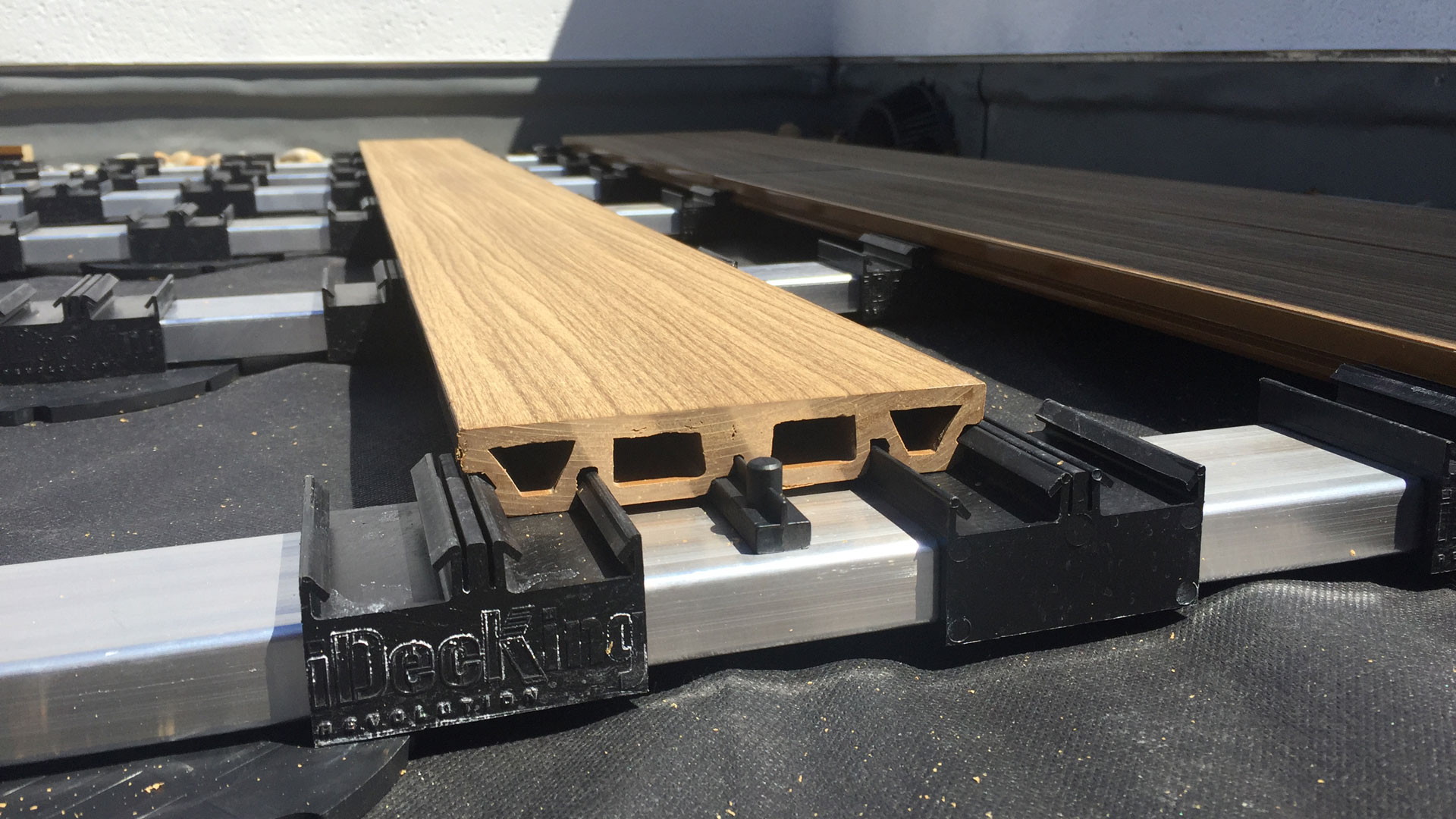

The Class A Rail Substructure system represents a significant advancement in the realm of outdoor paving solutions. Designed with precision, it offers a seamless integration between adjustable height pedestals, aluminium rail bearers, and a specially crafted lugged headpiece. This synergy ensures a heavy-duty substructure with outstanding weight tolerance, all while maintaining a minimal build-up of 47 mm, excluding the paving slab or porcelain tile.

Uncompromised Load Capacity

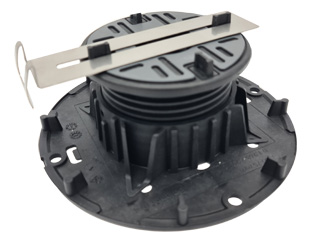

At the heart of this system lies the heavy-duty steel adjustable pedestals, coated with an exterior grade finish to withstand harsh conditions. Capable of supporting loads exceeding 2 tonnes each, these pedestals are the cornerstone of the system’s reliability and durability.

Fire Safety at its Core

Fire safety is a paramount concern in contemporary construction, and the Class A Rail Substructure excels in this arena. The rails are Class A1 rated according to EN 13501-1:2018 and fully comply with BS 8579 standards, offering peace of mind and enhanced safety for any outdoor space.

Seamless and Secure Integration

The system features specially profiled bearer rails and joists that effortlessly click onto Metalpad and MetalPad EX pedestals, eliminating the need for screw fixings. This design ensures a fully integrated substructure system with a seamless connection, offering greater spans between pedestals and additional lateral strength to the framework.

Installation Efficiency

Ease of installation is a critical factor in modern construction projects. The Class A Rail Substructure system addresses this need with its fast and straightforward assembly process, complemented by the provision of all necessary fixings and connectors.

Design Versatility

Catering to diverse architectural needs, the system offers a wide range of designs and sizes. Whether you’re working on a commercial terrace or a residential patio, height and shape variations can be easily achieved, ensuring that each project retains its unique character while benefiting from the system’s robust framework.

Sustainable and Maintenance-Free

In line with global sustainability efforts, the Class A Rail Substructure is manufactured from recycled aluminium, making it not only environmentally friendly but also fully recyclable. Moreover, its resistance to rotting, warping, and rusting minimises maintenance requirements, ensuring a long-lasting and eco-friendly solution.

Conclusion

The Class A Rail Substructure system is a testament to innovative engineering, marrying safety, durability, and environmental consciousness in a comprehensive paving solution. Ideal for those seeking a fire-rated, heavy-duty, and aesthetically pleasing outdoor flooring option, this system sets a new benchmark in the industry.

Embrace the future of non-combustible paving systems by exploring the Class A Rail Substructure. For more detailed information and to see how it can transform your outdoor spaces, visit Wallbarn’s Class A1 Rail Substructure System.

Adopting the Class A Rail Substructure means investing in the safety, stability, and sustainability of your exterior spaces. Embark on this journey to elevate your paving projects beyond the conventional, towards a safer, greener, and more resilient future.