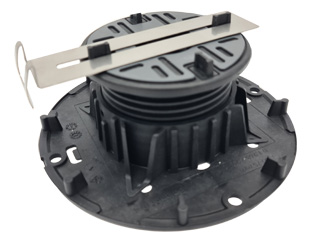

Introducing the MetalPad Ex Class A Pedestal, a non-combustible, fully adjustable pedestal system meticulously engineered for suspended decking and paving installations on exterior high-rise balconies, terraces, and flat roofs. This innovative product sets a new standard in the industry, combining unparalleled strength, durability, and precision with a commitment to fire safety and environmental responsibility.

A Fortress Against Corrosion

Constructed from mild steel conforming to EN 10152 standards, the MetalPad Ex pedestals are coated with Zintec 200, a superior anti-corrosion protective coating. This cutting-edge technology creates a robust barrier between the steel and aluminium components, ensuring exceptional resistance against corrosion and white rust formation. The Zintec 200 coating has undergone rigorous testing, demonstrating exceptional performance in Neutral Salt Spray Testing (NSST) and Cyclic Corrosion Testing (CCT), further solidifying its reputation as a formidable defence against harsh environmental conditions. It has also had a physical fire test with Warrington Fire and it is classified as Class A2 in accordance with EN 13501-1:2018.

Precision Engineering for Seamless Levelling

One of the standout features of the MetalPad Ex Class A Pedestal is its ability to facilitate precise levelling of the floor surface with millimetre accuracy. The threaded stem can be effortlessly twisted to adjust the height, even with the paving slab or rail/decking system already in place. There is a locking nut on the thread to secure the exact height long term. This ingenious design allows for seamless on-site adjustments, ensuring a flawlessly level installation every time.

Unwavering Strength and Stability

The MetalPad Ex has undergone rigorous independent weight testing by STS UK, a renowned authority in the field. The results are nothing short of remarkable, with the pedestal demonstrating an impressive weight tolerance of 49.86kN, approximately equivalent to a staggering 5,080kg. This unparalleled strength and stability make the MetalPad Ex an ideal choice for demanding, heavy-trafficked outdoor applications, providing peace of mind to architects, contractors, and homeowners alike.

A Versatile System for Diverse Applications

Designed with versatility in mind, the MetalPad Ex seamlessly integrates with a range of accessories, headpieces, and Wallbarn Aluminium Joists/Rails, enabling the creation of substructures for paving or decking projects that meet the stringent requirements of Class A specified projects. Whether you’re constructing a residential terrace, a commercial rooftop deck, or a public outdoor space, the MetalPad Ex system offers a comprehensive solution tailored to your specific needs.

Enhancing Safety and Sustainability

With zero plastic or rubber components, the steel MetalPad Ex Class A Pedestal, coated with Zintec 200 achieves an impressive Class A rating according to BS EN 13501-1: through physical fire tests carried out by Warrington Fire. This classification underscores the product’s exceptional fire resistance and commitment to safety, making it an ideal choice for projects where fire safety and real-life physical fire testing is of paramount importance.

Furthermore, the MetalPad Ex system aligns with sustainable building practices by promoting the recyclability of its steel components. This eco-friendly approach not only minimises environmental impact but also contributes to the overall longevity and durability of the installation.

Comprehensive Range of Components

To cater to diverse project requirements, the MetalPad Ex Class A Pedestal is available in a wide range of height options, from 26-35mm to an impressive 302-377mm. Additionally, the system offers various headpiece configurations, including Paving Headpieces, Self-Levelling Headpiecesand Crucifix Headpieces for paving applications, and the basic Flat Head for fixing to rails for decking, ensuring seamless integration with your chosen decking or paving materials.

Seamless Integration with Aluminium Joists/Rails

The MetalPad Ex is designed to work seamlessly with all Wallbarn aluminium Box & I-Plus joists/rails. These components can be effortlessly connected using the supplied Wing Nut Kit, which is hand-tightened initially and then firmly secured once the substructure is correctly positioned. This robust connection creates a strong and stable substructure, ensuring long-lasting performance and peace of mind.

Rail Headpiece: Accommodating Diverse Joist Widths

The Rail Headpiece, crafted from high-grade Aluminium 6063 T6 to BS EN 755-9 standards, offers a versatile solution for accommodating Box Rail Joists with a maximum width of 60mm. This headpiece is securely fastened to the MetalPad Ex pedestal and reinforced with a central screw, providing a robust and reliable connection for your decking or paving system.

Spreader Plate: Mitigating Point Loading

For installations on vulnerable subfloors, such as insulation or waterproof membranes, the MetalPad Ex system offers an ingenious solution: the Spreader Plate. Designed to significantly disperse weight and reduce point loading, the Spreader Plate is compatible with the MetalPad Ex Pedestal, Class A Fixed Height Pedestal, and Class A Joist Holder. By distributing the load over a larger surface area, the Spreader Plate safeguards the integrity of the underlying materials, ensuring a long-lasting and reliable installation.

Installation Considerations

The MetalPad Ex Class A Pedestal system is designed for installation on predominantly flat decks with sufficient structural integrity to support the weight of the system. Care should be taken to ensure that point loading does not occur under the baseplates, and the optional Spreader Plate should be utilised to increase the surface area and prevent puncturing of membranes or insulation.

Concrete Surface Installation

When installing the MetalPad Ex system on a concrete subfloor, it is crucial to consult the provided deflection tests to ensure optimal performance. Wallbarn recommends avoiding spans that result in a deflection greater than 5mm to maintain structural integrity and prevent excessive flexing or sagging.

Waterproofing Membrane/Insulation Installation

For installations on waterproof membranes, insulation, or vulnerable subfloors, it is essential to refer to the provided load and weight tolerance tests to determine the maximum recommended span for pedestal placement. Additionally, it is advisable to consult with the product manufacturer to ensure that the subfloor has the compressive strength to handle the desired spacing of the pedestals. In such cases, the use of the Spreader Plate is highly recommended to distribute the weight and reduce point loading, significantly increasing the weight tolerance of the pedestal.

Maintenance and Upkeep

To ensure the longevity and optimal performance of the MetalPad Ex Class A Pedestal system, regular maintenance is recommended. The cavities between the structural deck and the decking should be inspected at least once per year to ensure that drainage channels remain clear and free from debris or flammable materials. Water jets can be used to remove limited amounts of debris, taking care not to block or damage drainage outlets. For larger or compacted debris buildup, removal of the decking boards and manual or mechanical cleaning may be required.

Safety Considerations

While the MetalPad Ex Class A Pedestal system is designed with safety in mind, it is essential to follow proper precautions during installation and maintenance. Personal Protective Equipment (PPE), such as safety glasses, gloves, and dust masks, should be worn to protect against potential hazards like metal shavings and dust.

When cutting or drilling the aluminium components, it is recommended to use premium blades specifically designed for metal cutting to minimise sparks and reduce the risk of damaging the extruded profiles. Fragments cut from the pedestals may be hot, so caution should be exercised to avoid direct contact with surfaces such as waterproofing membranes.

Fire Safety and Emergency Response

As a Class A non-combustible product, the MetalPad Ex Class A Pedestal does not constitute a fire hazard. In the event of a fire, no specific fire-fighting measures are required for these products. However, it is essential to follow standard fire safety protocols and evacuate the premises immediately.

Handling and Storage

When handling the pedestals, it is crucial to adhere to both the Wallbarn Operations and Maintenance Manual and to the guidelines outlined in the Manual Handling Operations Regulations 1992. Appropriate Personal Protective Equipment (PPE), such as overalls, gloves, and safety boots, should be worn to reduce the risk of physical injury during installation and maintenance.

Environmental Considerations

Subsequent to manufacture, the MetalPad Ex Class A Pedestal is a stable product with no known adverse environmental effects. The recyclability of the steel components further contributes to its eco-friendly profile, promoting sustainable building practices and minimising environmental impact.

Conclusion

The MetalPad Ex Class A Pedestal from Wallbarn Ltd represents a groundbreaking solution for elevated decking and paving installations, combining exceptional strength, precision engineering, and fire safety with a commitment to sustainability and environmental responsibility. With its versatile range of components, seamless integration with aluminium joists/rails, and innovative features like the Spreader Plate, this system offers a comprehensive solution for architects, contractors, and homeowners alike. Backed by rigorous independent testing and a comprehensive 15-year limited warranty, the MetalPad Ex Class A Pedestal sets a new standard in the industry, redefining the possibilities of outdoor living spaces.