The client, a contractor, was tasked with removing the old timber decking and installing a new decking system that complied with new fire regulations for balconies and terraces. This was a challenging project due to the irregular shape of the terrace, which featured multiple curves, angles, upstands and pillars at various locations. Additionally, the client required the new decking system to match the previous timber decking, which ran diagonally to the perimeter.

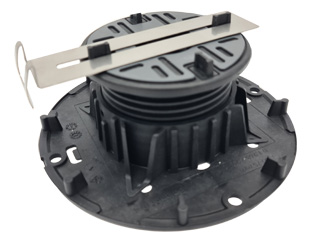

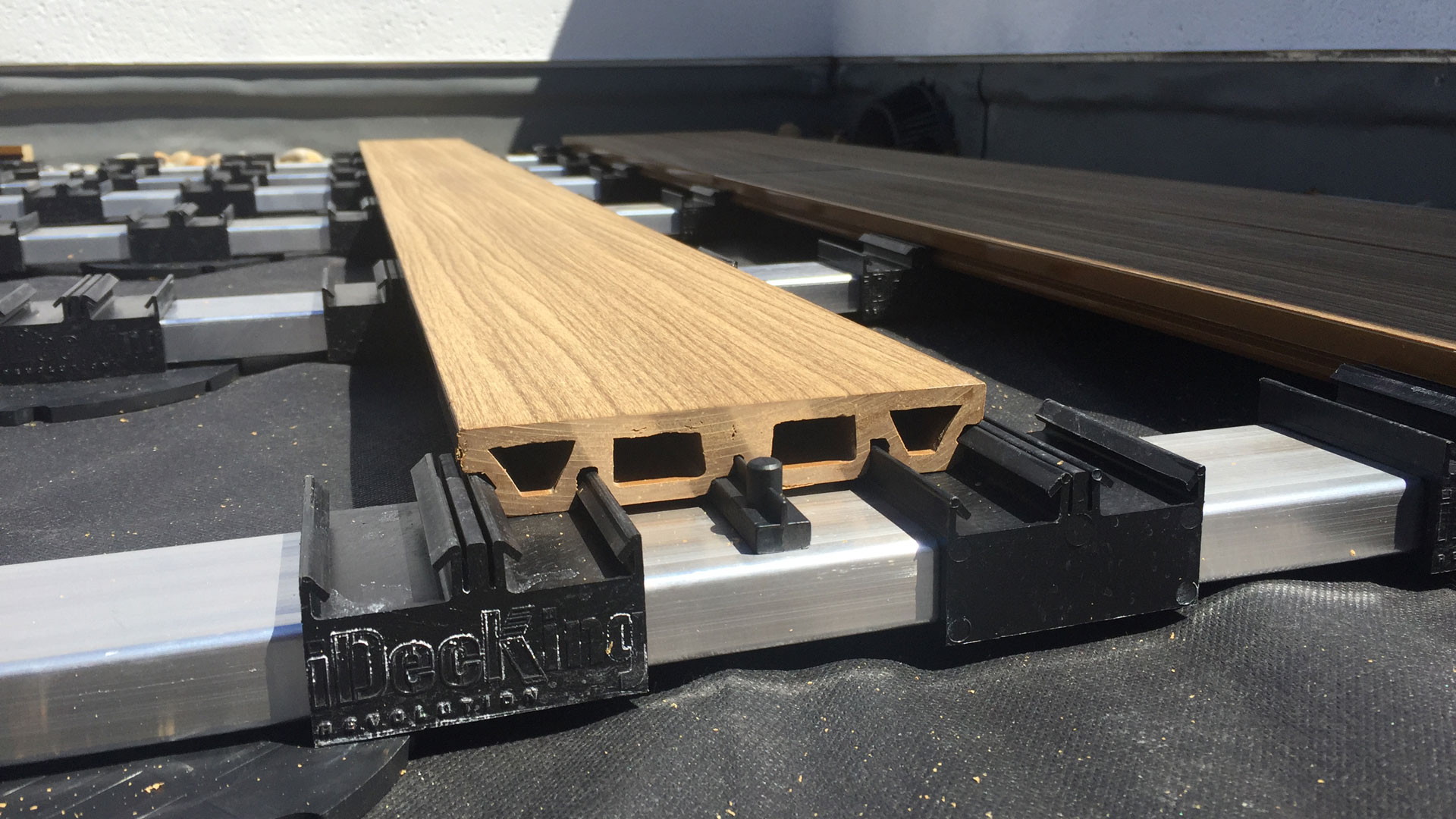

After a site visit, the design team created a layout for the two areas and liaised with the client to ensure that they were able to replicate the plan. The chosen system was the Exadeck Porcelain Decking from AB Commercial Building and Wallbarn’s Class A Substructure system. The Wallbarn adjustable metal pad for decking, together with their extensive range of aluminium joists, provided a secure fit without the necessity for mechanical fixings.

The design permits a slight movement of the joists, essential for accommodating differential rates of expansion and contraction.

The way in which the joists seamlessly work with the pedestals also sped up the installation process. To further strengthen the substructure stainless steel brackets, fixings and screws were used which provided a solid platform for the porcelain boards.

To cut the Exadeck boards effectively, a 30m diamond blade was used. Diagonal cuts were needed around the entire perimeter and the installers were pleasantly surprised to find that they could achieve a remarkably clean and precise cut without generating imperfections in the porcelain material. This precision allowed them to work efficiently with minimal wastage.

The Exadeck porcelain boards are of exceptional quality, making them ideal for premium projects. These boards undergo a rectification process which involves meticulously refining their dimensions along their length and across each horizontal plane.

As a result, these boards are perfectly flat with no curling or bending. The underside is also flat, ensuring they sit flush on Wallbarn’s wide joists. It should be noted that cheaper, alternative boards that are not made with the same rectification process can curl up at the edges meaning they will rock on the surface of the substructure even after the decking clip is fitted.

Exadeck proved to be the perfect solution for this complex project. The boards were expertly cut and securely fixed to the staircase frame. Additionally, it was laid across a narrow and lower height threshold in the wraparound terrace on the upper level.

The result was a very high-end finish with clean lines and consistent drainage gaps between the boards. This was in stark contrast to the original deck which had been ravaged by weather, making it uninviting and unappealing. The client now has a stunning deck that will last decades and will be safe in the knowledge of clearly meeting new fire regulations.

If you have any questions or need further information please don’t hesitate to contact us via email, or give us a call on 020 8916 2222.