Wallbarn has established itself as a leader in providing comprehensive substructure systems that cater to a wide range of decking and flooring needs. From adjustable pedestals to fire-rated components, Wallbarn’s product range is designed to meet the most stringent requirements of modern construction projects. In this article, we’ll explore why Wallbarn’s substructure systems are the intelligent choice for those seeking dependable and efficient solutions for their decking and flooring installations.

The Importance of a Robust Substructure

A well-designed substructure is the backbone of any successful decking or flooring project. It provides the necessary support, stability, and longevity that ensure the finished surface can withstand the test of time and various environmental factors. Let’s delve into why a robust substructure is crucial:

Foundation for Longevity

The substructure acts as the foundation upon which your decking or flooring rests. A high-quality substructure ensures that the surface remains level and stable over time, preventing issues such as sagging, warping, or uneven settling. This foundational support is essential for maintaining the integrity of the finished product for years to come.

Load-Bearing Capacity

One of the primary functions of a substructure is to distribute the weight of the decking or flooring evenly across the underlying surface. A well-engineered substructure can handle significant loads, accommodating foot traffic, furniture, and other weight-bearing elements without compromising the stability of the installation.

Moisture Management

In outdoor applications, effective moisture management is crucial to prevent water damage and extend the life of the decking or flooring. A properly designed substructure facilitates drainage and air circulation, reducing the risk of rot, mould, and other moisture-related issues that can compromise the integrity of the installation.

Adaptability to Uneven Surfaces

Many construction projects involve working with uneven or sloped surfaces. A quality substructure system, like those offered by Wallbarn, provides the flexibility to create a level surface even on challenging terrain. This adaptability ensures a smooth and even finish regardless of the underlying conditions.

Wallbarn’s Comprehensive Substructure Solutions

Wallbarn offers a wide range of substructure solutions designed to meet the diverse needs of decking and flooring installations. Let’s explore the key components that make up Wallbarn’s comprehensive substructure systems:

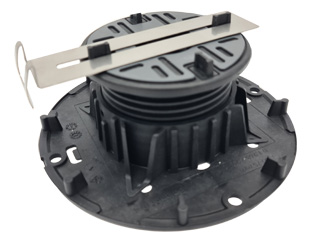

Adjustable Pedestals

At the heart of Wallbarn’s substructure systems are their innovative adjustable pedestals. These versatile components offer several advantages:

- Precise Height Adjustment: Wallbarn’s pedestals can be fine-tuned to achieve the perfect height, ensuring a level surface even on uneven substrates.

- Weight Distribution: The pedestals are engineered to distribute weight evenly, providing excellent stability for the finished surface.

- Easy Installation: With their user-friendly design, Wallbarn’s pedestals simplify the installation process, saving time and labour costs.

- Durability: Made from high-quality materials, these pedestals are built to withstand the elements and provide long-lasting support.

Aluminium Support Rails

Wallbarn’s aluminium support rails are a crucial component of their substructure systems, offering several benefits:

- Strength and Stability: The aluminium construction provides excellent strength-to-weight ratio, ensuring a stable foundation for decking or flooring.

- Corrosion Resistance: Unlike some traditional materials, aluminium rails resist corrosion, making them ideal for outdoor applications.

- Versatility: These rails can be easily cut to size and adapted to various layout designs, offering flexibility in installation.

- Compatibility: Designed to work seamlessly with Wallbarn’s pedestals and other components, these rails ensure a cohesive substructure system.

Fire-Rated Components

In response to increasingly stringent fire safety regulations, Wallbarn offers a range of fire-rated substructure components:

- Class A Rated Materials: Wallbarn’s fire-rated products meet the highest standards for fire resistance, providing peace of mind in sensitive applications.

- Compliance with Regulations: These components ensure compliance with current building codes and fire safety requirements.

- Versatility: Fire-rated options are available across Wallbarn’s product range, allowing for consistent fire safety throughout the substructure.

The Wallbarn Advantage: Innovation and Quality

Wallbarn’s commitment to innovation and quality sets their substructure systems apart from the competition. Let’s examine the key advantages that make Wallbarn the smart choice for reliable decking and flooring installations:

Cutting-Edge Design

Wallbarn’s products are the result of extensive research and development, incorporating the latest advancements in materials science and engineering:

- Optimised Load Distribution: The design of Wallbarn’s components ensures efficient weight distribution, maximising the stability of the finished surface.

- Innovative Connectors: Wallbarn’s system includes specially designed connectors that facilitate quick and secure assembly of the substructure.

- Adaptable Solutions: The modular nature of Wallbarn’s systems allows for easy customisation to suit various project requirements.

Superior Materials

The quality of materials used in Wallbarn’s substructure systems contributes significantly to their performance and longevity:

- High-Grade Plastics: Where applicable, Wallbarn uses advanced polymers that offer excellent durability and weather resistance.

- Premium Metals: The aluminium and steel components are carefully selected for their strength and corrosion-resistant properties.

- Environmentally Conscious Choices: Wallbarn incorporates recycled and sustainable materials where possible, aligning with modern environmental concerns.

Rigorous Testing and Quality Control

Wallbarn’s commitment to quality is evident in their thorough testing and quality control processes:

- Load-Bearing Tests: Each component undergoes rigorous load-bearing tests to ensure it meets or exceeds industry standards.

- Weather Resistance Trials: Outdoor components are subjected to simulated weathering to verify their long-term performance.

- Compliance Checks: All products are regularly assessed to ensure ongoing compliance with relevant building codes and regulations.

Versatility in Application

One of the standout features of Wallbarn’s substructure systems is their versatility across a wide range of applications. Let’s explore how these systems can be adapted to various decking and flooring scenarios:

Rooftop Terraces

Wallbarn’s substructure systems are particularly well-suited for rooftop terrace applications:

- Lightweight Design: The components are engineered to minimise additional load on the roof structure.

- Water Management: Integrated drainage features help protect the underlying roofing membrane.

- Height Adjustability: Easy adjustment allows for level surfaces even on sloped roofs.

Balconies and Patios

For balcony and patio installations, Wallbarn’s systems offer several advantages:

- Space Efficiency: The compact design of the substructure components maximises usable space.

- Easy Retrofitting: Wallbarn’s systems can be easily installed over existing surfaces, simplifying renovation projects.

- Aesthetic Flexibility: The substructure can accommodate various decking and flooring materials to suit different design preferences.

Commercial Spaces

In commercial applications, Wallbarn’s substructure systems provide the reliability and performance required for high-traffic areas:

- High Load Capacity: Engineered to support heavy foot traffic and commercial furniture.

- Quick Installation: Time-saving features reduce downtime during installation or maintenance.

- Accessibility: The design allows for easy access to underlying services or utilities when needed.

Installation Efficiency and Support

Wallbarn’s substructure systems are designed with the installer in mind, offering numerous features that enhance efficiency and ease of use:

User-Friendly Design

The components of Wallbarn’s substructure systems are engineered for straightforward installation:

- Intuitive Assembly: Clear instructions and logical design make assembly straightforward, even for those new to the system.

- Minimal Tools Required: Many components can be installed with basic hand tools, reducing the need for specialised equipment.

- Pre-fabricated Elements: Where possible, Wallbarn incorporates pre-fabricated elements to speed up on-site assembly.

Comprehensive Support

Wallbarn provides extensive support to ensure successful implementation of their substructure systems:

- Technical Documentation: Detailed installation guides and technical specifications are readily available.

- Expert Consultation: Wallbarn’s team of specialists is on hand to provide advice and support throughout the project lifecycle.

- Training Opportunities: Wallbarn offers training sessions to familiarise installers with their products and best practices.

Sustainability and Environmental Considerations

In an era of increasing environmental awareness, Wallbarn’s substructure systems are designed with sustainability in mind:

Eco-Friendly Materials

Wallbarn incorporates environmentally responsible materials into their products:

- Recycled Content: Many components contain a high percentage of recycled materials, reducing the demand for virgin resources.

- Recyclability: At the end of their life cycle, many of Wallbarn’s products can be recycled, minimising waste.

- Low-Impact Production: Manufacturing processes are optimised to reduce energy consumption and emissions.

Long-Term Durability

The longevity of Wallbarn’s substructure systems contributes to their environmental profile:

- Reduced Replacement Frequency: The durability of the components means less frequent replacements, reducing waste over time.

- Minimal Maintenance: Low maintenance requirements translate to fewer resources needed for upkeep.

- Adaptability: The ability to reuse and reconfigure components extends their useful life.

Cost-Effectiveness and Return on Investment

While the initial investment in a quality substructure system may be higher, Wallbarn’s solutions offer significant long-term cost benefits:

Reduced Maintenance Costs

The durability and quality of Wallbarn’s components translate to lower maintenance expenses:

- Fewer Repairs: High-quality materials and construction reduce the likelihood of costly repairs.

- Extended Lifespan: The longevity of the substructure means less frequent replacement of the entire system.

- Easy Upkeep: Simple maintenance procedures help keep the system in optimal condition with minimal effort.

Improved Project Efficiency

Wallbarn’s systems can lead to cost savings through improved project efficiency:

- Faster Installation: User-friendly design and pre-fabricated elements speed up the installation process, reducing labour costs.

- Reduced Material Waste: Precise engineering and modular design minimise on-site waste, lowering material costs.

- Versatility: The ability to adapt the system to various projects reduces the need for multiple specialised solutions.

Compliance with Industry Standards and Regulations

Wallbarn’s commitment to quality extends to ensuring their substructure systems meet or exceed relevant industry standards and regulations:

Fire Safety Compliance

With increasing focus on fire safety in construction, Wallbarn’s fire-rated components offer peace of mind:

- Class A Ratings: Many components achieve the highest fire resistance ratings, meeting stringent safety requirements.

- Comprehensive Testing: Products undergo extensive fire safety testing to verify their performance.

- Documentation: Detailed fire safety certifications are available to support compliance documentation.

Load-Bearing Standards

Wallbarn’s systems are engineered to meet or exceed load-bearing requirements:

- Structural Integrity: Components are designed and tested to withstand specified loads with appropriate safety factors.

- Compliance with Building Codes: The systems are developed with consideration for various international building standards.

- Performance Verification: Regular testing ensures ongoing compliance with load-bearing requirements.

Case Studies and Real-World Performance

While specific case studies are not the focus of this article, it’s worth noting that Wallbarn’s substructure systems have been successfully implemented in a wide range of projects across various sectors. The real-world performance of these systems consistently demonstrates their reliability, versatility, and effectiveness in supporting high-quality decking and flooring installations.

Conclusion: The Smart Choice for Reliable Installations

In conclusion, Wallbarn’s substructure systems represent the smart choice for professionals seeking reliable, efficient, and versatile solutions for decking and flooring installations. With their innovative design, high-quality materials, and comprehensive support, Wallbarn offers a range of benefits that set their products apart:

- Superior Performance: Engineered for stability, durability, and longevity.

- Versatility: Adaptable to a wide range of applications and project requirements.

- Efficiency: User-friendly design and installation support streamline the construction process.

- Sustainability: Eco-friendly materials and long-term durability contribute to environmental responsibility.

- Cost-Effectiveness: Long-term savings through reduced maintenance and improved project efficiency.

- Compliance: Meeting or exceeding industry standards and regulations for safety and performance.

By choosing Wallbarn’s substructure systems, construction professionals can ensure a solid foundation for their decking and flooring projects, delivering superior results that stand the test of time. As the construction industry continues to evolve, Wallbarn remains at the forefront, providing innovative solutions that meet the challenges of modern building practices.